Steel Cord Conveyor Belt

Steel cord rubber conveyor belt is suitable for coal mines, mines, ports, electric power, metallurgy, building materials and other industries under the condition of anti-tearing material transport, can be used for long distance, large span, large volume and high speed material transport.

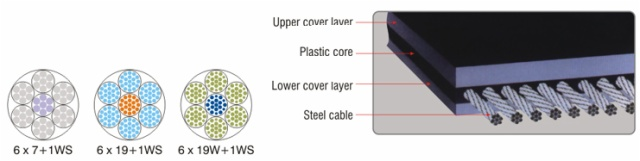

The belt is made up of core rubber, wire rope, cage cover layer and edge glue, with mildew proof, moth-proof, anti-aging, good heat resistance, high tear strength and belt surface can be refurbished after bad advantages. Features high tensile strength. Good impact resistance, long service life, small elongation, good slotting, good flexural resistance for long distance, large haul, high speed conveying materials.

Characteristic

- High allowable strength and high safety factor;

- The elongation is very small, the tensioning stroke distance is short;

- Steel wire rope and rubber firmly combined, excellent dynamic performance;

- The belt body is soft, good slotting, good linear running;

- Excellent impact resistance;

- The joint is reliable, long service life.

Adhesion of Steel Cord

| Strength | ST | ST | ST | ST | ST | ST | ST | ST | ST | ST | ST | ST | ST |

| 600 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3150 | 4000 | 4500 | 5000 | 5400 | 6300 | |

| Adhesion N/mm | 54 | 60 | 64 | 69 | 74 | 84 | 98 | 108 | 118 | ||||

| GB9770-88 | |||||||||||||

| Adhesion N/mm | 60 | 70 | 80 | 95 | 105 | 105 | 130 | 140 | 145 | 150 | 165 | 175 | 180 |

| DIN22131-88 |

Standard Specifications

| Belt strength | Cord diam d(mm) | Pitch P | Standard working | Standard rubber cover | Belt weight | Min.Pulley | Cord strength | |

| (st-No.) | Cord structure | (mm) | tension(N/mm) | thicknes t1t2(mm) | (Kg/㎡) | diam.(mm) | KN/piece | |

| ST-630 | 3 | 6*7+1WS | 10 | 90 | 5*5 | 20 | 800 | 6.93 |

| ST-800 | 3.5 | 6*7+1WS | 10 | 110 | 5*5 | 20.6 | 800 | 8.8 |

| ST-1000 | 4 | 6*7+1WS | 12 | 140 | 6*6 | 24.7 | 800 | 13.2 |

| ST-1250 | 4.5 | 6*7+1WS | 12 | 175 | 6*6 | 25.4 | 800 | 16.5 |

| ST-1600 | 5 | 6*19+1WS | 12 | 225 | 6*6 | 26 | 1000 | 21.12 |

| ST-2000 | 6 | 6*19+1WS | 12 | 285 | 8*6 | 30 | 1000 | 26.4 |

| ST-2500 | 7.5 | 6*19W+1WS | 15 | 355 | 8*6 | 32.2 | 1250 | 41.25 |

| ST-3150 | 8.1 | 6*19W+1WS | 15 | 450 | 8*8 | 35.7 | 1400 | 51.98 |

| ST-4000 | 9.1 | 6*19W+1WS | 17 | 570 | 8*8 | 37.8 | 1600 | 74.8 |

| ST-4500 | 9.7 | 6*19W+1WS | 16 | 645 | 8*8 | 38.7 | 1800 | 79.2 |

| ST-5000 | 10.9 | 6*19W+1WS | 17 | 715 | 8.5*8.5 | 41.9 | 1800 | 93.5 |

| ST-5400 | 11.3 | 6*19W+1WS | 17 | 760 | 9*9 | 43.9 | 2000 | 101 |

| ST-6300 | 12.3 | 6*19W+1WS | 18 | 900 | 10*10 | 48.3 | 2000 | 124.74 |

Number of Steel Cords

| Belt width(mm) | ST | ST | ST | ST | ST | ST | ST | ST | ST | ST | ST | ST | ST |

| 600 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3150 | 4000 | 4500 | 5000 | 5400 | 6300 | |

| 800 | 75 | 75 | 63 | 63 | 63 | 63 | 50 | 50 | |||||

| 1000 | 95 | 95 | 79 | 79 | 79 | 79 | 64 | 64 | 56 | 60 | 56 | 56 | 52 |

| 1200 | 113 | 113 | 94 | 94 | 94 | 94 | 76 | 76 | 68 | 72 | 68 | 68 | 63 |

| 1400 | 133 | 133 | 111 | 111 | 111 | 111 | 89 | 89 | 79 | 84 | 79 | 79 | 74 |

| 1600 | 151 | 151 | 126 | 126 | 126 | 126 | 101 | 101 | 91 | 96 | 91 | 91 | 85 |

| 1800 | 171 | 143 | 143 | 143 | 143 | 114 | 114 | 103 | 107 | 103 | 103 | 96 | |

| 2000 | 159 | 159 | 159 | 159 | 128 | 128 | 114 | 120 | 114 | 114 | 107 | ||

| 2200 | 176 | 141 | 141 | 125 | 133 | 125 | 125 | 118 | |||||

| 2400 | 193 | 155 | 155 | 137 | 146 | 137 | 137 | 129 |

Grades

| Test items | Property indexes | |||||

| GB700-88 | DIN22131-88 | |||||

| Class H | Class M | Class W | Class X | Class Y | ||

| Tensile strength | Mpa≥ | 17.65 | 13.73 | 18 | 25 | 20 |

| Elongation at break | %≥ | 450 | 400 | 400 | 450 | 400 |

| After aging | % | -25~+250 | -25~+250 | -25~+250 | -25~+250 | -25~+250 |

| Change rate of tensile strength | ||||||

| Change rate of elongation | ||||||

| Abrasion | ≤ | 0.6cm3/1.61Km | 0.8cm3/1.61Km | 90cm3 | 120cm3 | 150cm3 |

Related Products

Oil Resistant Conveyor Belt

Corrugated Sidewall Conveyor Belt

Shot Blasting Conveyor Belt