Sidewall Conveyor Belts

The sidewall conveyor belt is a large inclination angle wave sidewall conveyor belt. The sidewall conveyor belt was first successfully developed by the British company and began to promote it.

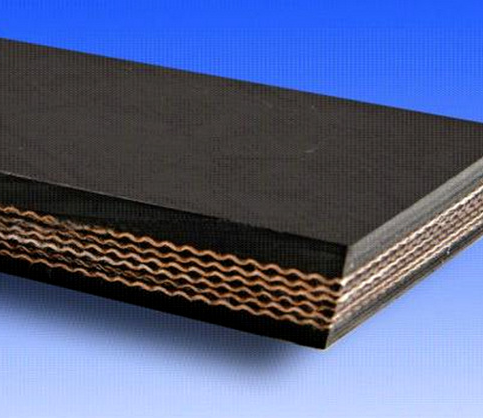

The large inclination wave sidewall belt is composed of baseband, sidewall and transverse partition plate.The edge acts to prevent slip and drop of materials.In order to bypass the drum, the gear edge is designed as corrugated; the transverse partition is to carry the material, and T type TC is adopted.The edge and transverse partition are connected with base band by secondary vulcanizing and with high connection strength.

Wave sidewall conveyor belt varieties: according to the different cover rubber performance, it is divided into ordinary type, heat resistance type, refractory type, cold resistance type, acid and base resistance type, oil resistance type, etc.

Specification of sidewall conveyor belt:

(1) Belt core material: CC-56, NN100, NN150, NN200, NN300, NN400;

(2) Bandwidth: 100mm-2,400 m m;

(3) Cloayer: 2-10;

(4) Cover covering:

Working face: 1.5-8mm;

Non-face: 0mm-4.5mm

The belt core material of the sidewall conveyor belt

Cotton Canvas Core CC-56

Nylon cloth core NN100, NN150, NN200, NN300, NN400, NN500

The polyester cloth core is EP100, EP150, EP200, EP300, EP400, EP500

Wire rope core ST1000-ST5400

Height of the retaining edge (mm): S80, S100, S120, S160, S200, S240, S300, S400, S500

Height of the partition (mm): TC75, TC90, TC110, TC140, TC180, TC220, TC280, TC380, and TC480

General writing method: like B800 * 6 (3 + 3 + 1.5) * 110 meters

S120-120 TC110-252-460

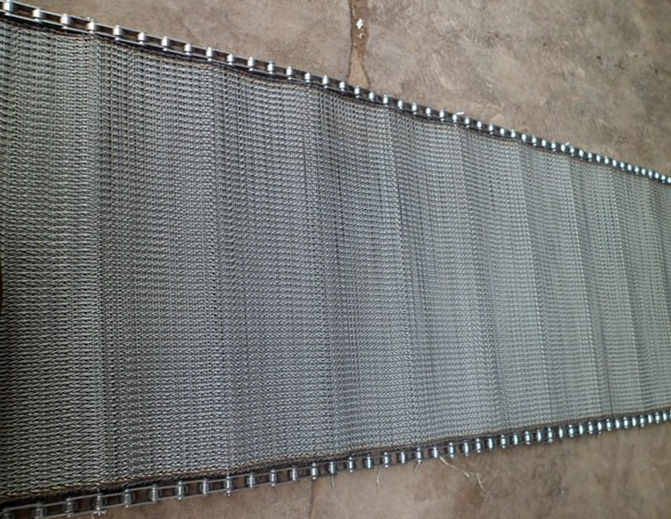

Metal sidewall conveyor belt

Metal sidewall conveyor belt: generally for a combination of balanced four string single head net belt, string do not wear to both sides of the edge each turn 15-30 cm high edge, to block the object from falling.Such as chemical fiber factory, standard parts heat treatment, bearing parts cleaning machine with edge turning net, used to block the spillover of chemical fiber, etc.

Metal retaining edge conveyor belt: materials of A3 low carbon steel, 45 # steel, 1Cr13 heat resistant steel, stainless steel, 304 stainless steel, 1Cr18Ni9Ti stainless steel, 0Cr18Ni14NO2CU2 heat resistant acid resistant steel, etc.

Metal retaining edge conveyor belt

Metal sidewall conveyor belt: annefurnace net belt, baking oven net belt widely used in glass products industry.Food processing industry, dehydrated vegetables, frozen food single frozen machine preprocessing network belt, chain network.Powder metallurgy, metal heat treatment, quenching, sintering, brazing, baking, bright, black, bearing, carburized high temperature furnace mesh belt, baffle mesh belt, coating drying trunk conveyor belt, foam nickel reduction production line network belt, washer, elevator, dryer, dryer, curing furnace mesh belt.Each transmission process chain network and network belt.

Note for the use of the conveyor belt

With the popularity of conveyor belt in industrial production, multi-variety, high performance, lightweight, multi-functional, long life are several aspects of producers.In industrial production, the correct use of conveyor belt is particularly important, in the use of conveyor belt should be paid attention to the following matters:

- Avoid the roller being covered by the material, causing poor rotation, prevent the leakage from being stuck between the roller and the tape, pay attention to the lubrication of the active part of the conveyor belt, but not the oil conveyor belt;

- Prevent the conveyor belt load from starting;

- If the conveyor belt deviation, timely measures should be taken to correct it;

- When the conveyor belt is partially damaged, artificial cotton is used to repair it in time to avoid expansion;

- Avoid the conveyor belt from rack, pillar or block block to prevent breaking and cracking.

Optimization and improvement of the sidewall conveyor belt

In order to improve the carrying capacity of the conveyor belt, the lateral bending deformation of the transmission belt is the minimum, that is, improving the lateral rigidity of the conveyor belt is the key to reduce the lateral carrying deformation of the belt and increase the carrying capacity of the belt.The lateral rigidity value of the retaining edge conveyor belt refers to the ratio of the bending underweight and the band width quantity value of the belt due to the retaining edge conveyor belt body body weight in the lateral vertical cross section of the belt.The technical standard requirements of the lateral rigidity value of the belt conveyor belt with high lateral rigidity are not greater than 0.05. After the optimization and improvement of the belt structure, the lateral rigidity detection value is 0.036, and the lateral deformation of the belt load decreases, which can improve the carrying capacity by 15%~20%.An effective measure to improve the lateral rigidity of the large heavy-load edge conveyor belt is to set a special composite tape layer with special mixing and compression between the canvas layer of the flat base band body, that is, the polyester short fiber is buried in the transverse single direction along the belt body in the tape layer.The use of this dedicated composite layer that enhances the lateral bending ability of the retaining belt increases the lateral rigidity value of the belt by 2.5 times compared with the retaining belt of the ordinary structure, even if the lateral rigidity value increases from 0.09 to 0.036.

Characteristics of the sidewall conveyor belt

- Small land area and less investment;

- Increase the transmission angle (30~90 degrees);

- Large transportation volume and higher promotion height;

- Low energy consumption, simple structure, high tape strength and long service life.

- Stable transition from horizontal to inclined (or vertical);

- Suitable for conveying powder, granular, small block, paste and liquid materials that are easy to scatter;

- According to the coating performance, the varieties are divided into ordinary, heat-resistant, refractory, cold-resistant, acid-alkali resistant, oil-resistant, etc.

Ahaa, its good conversation concerning this piece

of writing at this place at this weblog, I have read all that, so now me also commenting at this place.

Thanks。

We are likely to share our idea . what ever , any sugggestion we are happy to received .