Your Conveyor Belt Should Be Maintained

Your conveyor belt should be maintained

conveyor belt maintance

Good daily maintenance and maintenance, can make the conveyor with better life and performance. According to the statistics of the good and bad maintenance can be at least 35% difference of the service life. This means 35% of the cost, which will be no big cost for a long distance conveyor.

Qingdao Jahung Conveyor belt Co.,ltd , have been professional conveyor belt manufacturer 42 years , now we share some knowledge for maintenance of the conveyor belt.

conveyor belt maintanced

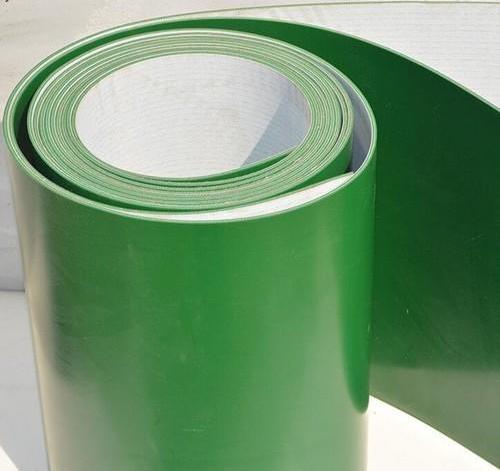

- The conveyor belt shall be kept clean during transportation and storage. Avoid direct sunlight or rain, snow immersion, to prevent contact with acid, alkali oils, organic solvents and other substances, and it is only one meter away from the heating device.

- During the storage time, the temperature in the warehouse area should be kept between-18℃ -40℃, and the relative temperature should be kept between 50-80%RH.

- During storage, the products shall be placed in volume and not folded. During storage, they shall be turned once a quarter during storage.

conveyor belts maintance

4. Different types, specifications of the conveyor belt should not be used together, its joint is best to use bonding method.

- The type, structure, specification and layer number of the conveyor belt should be reasonably selected according to the use conditions.

- The running speed of the conveyor belt should generally not be large and 2.5 m / s, and the materials with large block degree and large wear and tear and the fixed plow unloading device should be used at low speed as far as possible.

7.The relationship between the diameter of the conveyor belt, the matching of the transmission roller and the corner of the roller shall be reasonably selected according to the design provisions of the conveyor.

- The feeding direction shall follow the running direction of the tape. In order to reduce the impact on the material falling, the chute shall be used to reduce the falling distance of the material; the belt receiving section shall shorten the roller distance and adopt the buffer roll. To prevent material leakage, the belt side shall avoid the strong baffle and scraping the surface of the conveyor belt.

- The following matters should be paid attention to when using the conveyor belt:

(1) Avoid the roller is covered by the material, resulting in poor rotation, prevent the leakage of material stuck between the drum and the tape, pay attention to the lubrication of the active part, but do not have oil conveyor belt;

(2) Avoid starting with load;

(3) If the tape deviates, timely measures should be taken to correct it;

(4) The local operation of the tape found should be repaired in time, so as to avoid expansion;

(5)Avoid tape suffering from rack, pillar or block material block, to prevent cracking;

pvc conveyor belt maintance

Leave a Reply

Want to join the discussion?Feel free to contribute!