Conveyor Belt Manufacturers Tell You Some Thing

We are Chinese professional Rubber conveyor belt manufacturer , we have made conveyor belt from 1980s , we think we should share some knowledge for conveyor belt delay usage .

1.Why are the conveyor belt joints easy to crack and disconnect?

The strength of the conveyor belt joint is lower than that of the normal belt body.General mechanical connection, the joint strength can only reach 40-50% of the belt strength, when the cold joint quality is good, the joint strength can reach 60-70%, and the thermal joint strength can reach 80-90% (the joint method is correct, no quality defects).Because the strength of the joint is relatively low.Incorrect bonding mode will cause the strength of the joint, such as cutting, grinding damage to the next layer of cloth, excessive grinding, overlapping, etc

The connection length is not enough, the number of steps is not enough, the rubber joint rubber is not good or has been damaged since the sulfur failure, wire rope excessive grinding, wire rope rust, the strength of the joint will be greatly reduced, easy to crack when use (surface glue part).

2.

2.

2.What is the cause of the belt slip?

When the conveyor belt shall be operating normally, the belt speed shall not be less than 95% of the drum speed.If the friction between the roller and the conveyor belt is not enough, the conveyor belt slides very easily.There are many reasons for insufficient friction between roller and conveyor belt, including: insufficient tension, load start, insufficient roller surface friction coefficient, etc.The reasons for insufficient tension are: insufficient tension travel, insufficient weight and long conveyor belt; insufficient friction coefficient of roller surface is excessive rubber grinding damage, wet or lubricating oil, and material (easy to damage, soluble in water).

3.What are the requirements for rubbermaterial and slurry storage?

Film and rubber glue shall be kept in dark and dry places to avoid direct sunlight, radiation and away from the source of fire.Film and rubber glue shall be kept in places with large dust to avoid various chemicals in contact with them.The ambient humidity of preserving the film and slurry is 50-75%, and the temperature shall not be less than 5°C and not more than 35°C.Storage period of film and jelly: 1 month in summer, 2 months in winter and 1 month in spring.

-

Conveyor belt jointmethod .

Our company suggests that the conveyor belt bonding by hot glue, the middle needs to stick the core rubber, each step can only have one-layer of cloth, the joint direction should run along the direction of the conveyor belt.

-

How to repairthe middle of the wire belt verticallytearing for 14-15 meters. How to repair it?

The upper and lower covering glue of the damaged part can be stripped (50-100mm over the damaged part and 30-50mm over the damage part), taking a section of rubber the same size as the stripped part (preferably with a layer) and then repair it according to the cold glue method.

-

Method of hot glue peeling (is one end edge glue removed)?

This is another method of bonding, this method is ok, but if used, note the following:

- Be sure to use the sealing glue;

- The intersection of the edge glue part must be connected by the vulcanized rubber;

- The connected parts of the rubber must be polished

Disadvantages, if it is not handled well, the edge glue part is easy to damage.

7.Comparison of EP high temperature resistant belt and cotton canvas high temperature resistant belt:

Same point: the surface covering glue is the same.Different points: cotton canvas can withstand a maximum temperature of 150°C; EP-TNG canvas can be used at 200°C and can be used at 220°C;

Cotton canvas high temperature belt adhesion is relatively low, EP high temperature belt adhesion is relatively high;

The service life of EP high temperature resistance belt is significantly longer than that of cotton canvas.

-

Can the core glue of different manufacturers be mixed?

It is not recommended to mix the core glue of different manufacturers, because the different formula of different manufacturers.There are many kinds of complexes in rubber, and some will have interactive reactions. In the formula of the same manufacturer, there will be no adverse interactive reactions, but different formulas of different manufacturers differ greatly. Using core glue from different manufacturers together, there may be an interactive reaction of partners, which may affect the use effect of core glue.

-

Can the joint temperature reach 120°C, but it does not reach the normal sulfide temperature?

be not allowed.The normal sulfide crosslinking temperature of the rubber is determined by the sulfides and promoters in the rubber. In order to ensure the safety of the rubber processing, the general manufacturer will not set the sulfide starting temperature of the rubber used in the conveyor belt at a very low level.Therefore, when the temperature reaches 120°C, the rubber does not enter the normal sulfation state, therefore, the quality of the conveyor joint will be greatly affected.Usually, when the sulfization temperature is higher than the critical temperature of the promoter and sulcanator and fails to reach the normal sulfide temperature, the method of extending the sulfization time can be adopted, so that the sulcanization of rubber can meet the requirements.The general temperature extends 2-4 times below 10°C.Of course, for performance considerations, we do not recommend a low temperature long sulization method.

-

Why is the fabric grain dense and thick?

The density of cloth, thickness and the variety, strong grade of cloth.Because the modulus and strength of different fibers are different, so to achieve the specified strength, it is necessary to take different diameters, different Dan fibers, yarn, so the density and thickness of cloth appear, -speaking, polyester is thicker than nylon, but also thicker than nylon; strong cloth is lower than strong cloth, thick.

-

Why do other construction units generally do not advocate the use of sealing glue?

The effect of sealing glue is mainly to connect the two ends of sulfur, and also to prevent the intrusion of harmful media such as water, and to prevent the sweeper from damaging the joint.Therefore, to synchronize the service life of the sulfide joint with the tape, the sealing glue must be used to extend the service life of the tape.The use of sealing glue will increase the cost, but also improve the difficulty of the glue joint, so some construction units will not advocate the use of sealing glue.In fact, this has a negative impact on the service life of the conveyor belt.

12.Can not put the core glue, but apply a few more layers of glue paste?

The glue paste is a glue substance with- -fixed viscosity formed by dissolving the core glue in the solvent.After all the solvent is volatilized, the composition is exactly the same as the core glue, however, the commonly used colloid is made with the core glue and the solvent (such as toluene, xylene, solvent gasoline, etc.) according to the ratio of 1:5-1:6.Core glue is a film deferred by the press press, its molecular arrangement sequence is oriented, from a mechanical point of view, so the tensile performance and fatigue resistance along the direction of the press press are good.However, the arrangement of the rubber molecules in the solvent is random and isotropic.The role of the rubber paste is through the good solvent fluidity, permeability of the yong ji rubber can fully enter between the fabric, so that the rubber can be better combined with the fabric together.Therefore, the role of core glue is to make the conveyor belt adhesive to- -, at the same time eliminate the difference between conveyor belt stress, deformation caused by different thickness, and absorb some destructive energy, so core glue is an integral part of the conveyor belt, some foreign manufacturers in order to extend the service life, often use the thickness of thickened core glue.

Only use the brush glue paste without the core glue, so the thickness of the interlayer glue at the joint is relatively thin, and its use effect will also have an impact.

-

When pulling the head, I found that the glue was attached to one layer of cloth, while the other layer is light. Why?(Is it best to have as much glue on the fabric on both sides?) There are several reasons why the adhesive is attached to the first layer of cloth:

a.Attachment is not good.

b.The adhesion is better, but the adhesive strength is higher.Generally speaking, nylon belt, some EP belt in the pull, it is easy to have glue two times, and the thickness of the glue is the same, and cotton canvas belt is easy to appear the above- -layer cloth attached with glue, the other layer is light.Of course, this will also occur in some EP bands with poor adhesion or EP bands with better adhesion but higher adhesive strength.

-

Why do you feel that the joint is harder than other parts?

The process of conveyor belt sulfide bonding is actually the process of continued crosslinking of the already sulfide rubber.Because sulphalization requires heating and pressure, and needs a long time, after a long time of sulphalization, the hardness of sulfide rubber will improve, so the joint part is harder than other parts.

-

Run when the edge glue wear and cause to decaying. How to deal with it?

In the case of small decaying area, you can take the method of cold glue to repair, but we must pay attention to empty the air.Of course, the best way is to correct when the conveyor belt is deviation.

-

Can the roller package rubber be treated with hot glue?

The roller coating can be cold on site, but the site treatment is not good.Heat treatment can generally be used for more than 5 years, and will not cause the roller coating to fall off due to accidental circumstances.

-

How to connect the two conveyor belts with different layers?

This method can not be used in general.But when some accidents happen, the scene has to take this method when the emergency is needed.When using this method, it is best to put a layer to two layers at the bottom, and put the sealing glue to eliminate the shadow of the inconsistent thickness of the conveyor joint at both ends

-

What are the advantages and disadvantages of EP belt and NN belt?

NN conveyor belt is an alternative to cotton canvas conveyor belt, which has the advantages of high strength and good fatigue resistance, but the use extension rate of NN conveyor belt is relatively large and easy to elongation;

EP belt is an upgrade product of NN belt, which has the advantage of the advantages of nylon conveyor belt, and has a wider range due to the small elongation rate in use.However, the EP canvas and rubber are not better than NN canvas, so the adhesive

In terms of safety performance, the EP conveyor belt is inferior to the NN conveyor belt.

-

Is the long conveyor belt easy to deviate?

During the operation of the conveyor belt, sometimes there will be a partial deviation phenomenon.In general, due to the problem of the conveyor belt itself caused by the conveyor belt deviation is not common, the conveyor belt deviation is mainly the reason of the conveyor.For the conveyor, the roller is not parallel, the support is not true, and the roller rotation is not flexible.For the relatively short conveyor belt, due to the greater probability of unilateral roller rotation and some other factors, the possibility of conveyor belt deviation is relatively greater, and the longer conveyor belt, due to the increase of the number of rollers, the impact of unilateral improper lining will reduce, so the deviation phenomenon on the conveyor belt will be less.

Of course, except in some cases, such as: when the centering support roll swing is not flexible or is tilted and fixed, the roller surface is not clean enough, which can cause the conveyor belt deviation.

-

What is caused by the above conveyor belt and the following?

The upper and lower sides of the conveyor belt are mutually influential and independent of each other.one.In the case, the lower side deviation, and the normal upper side is basically due to the poor cleaning device, the lower roller stick material, the heavier roller is not parallel, or the inclined counterweight bracket, the lower roller is not parallel to each other, the specific situation should be adjusted according to the actual situation.Generally speaking, the lower side deviation can be corrected by improving the working condition of the cleaning device, removing the materials attached to the roller, adjusting the lower side leveling roller, the V type roller on the lower side, or installing the lower side centering roller.

21.Why is it easy to run away in rainy days?

On rainy days, the open conveyor belt is easy to touch water, and the rollers and rollers of the conveyor belt are also easy to be wet.The wet friction coefficient of rubber and metal is relatively small. If the roll rotation is not flexible or the roller surface sticks to the material, then the conveyor belt on the roller will be uneven, or the resistance on both sides is inconsistent. At this time, the conveyor belt will lose its balance and appear deviation.The thickness of the water film between and the conveyor belt will increase, prone to skid phenomenon, making the conveyor belt deviation.

-

How to handle the longitudinal joint found at the joint?

The longitudinal joint of the conveyor belt mainly appears on a wide or particularly narrow conveyor belt, in which it is relatively easy to overlap.Different bonding processes are not affected by the longitudinal joint.If the process used in the conveyor belt is not connected, then the longitudinal joint will basically not have an adverse impact on the joint. If it is going to be connected, then the tie joint will have a large local thickness problem.In the operation, we should pay attention to layer by layer clear, a single layer should be stripped will be all stripped, can not rest, should not be peeled off can not move it.

-

If the joint part cracks after vulcanization, can it be repaired with cold glue?

ability.After the cracking of the joint part after vulcanization, the conveyor belt should be cleaned up during the treatment, and the gas in the cracking part should be fully discharged. If the gas cannot be discharged, the belt can be carried out.Make a hole and repair the hole after repair.You can also dig out the cracked part, stick it with an adhesive, or repair the cracking site with a hot repair method.

-

How to determine the length of the joint?

The joint length is determined according to the variety, number of layers and the effective width of the skeleton material of the conveyor belt, two vulcanizers can be used and treated with the relevant materials where the intersection of the two is connected to ensure the smooth transition of the two vulcanators.

-

How to distinguish between NN and EP?

The appearance difference between NN and EP conveyor belt is:

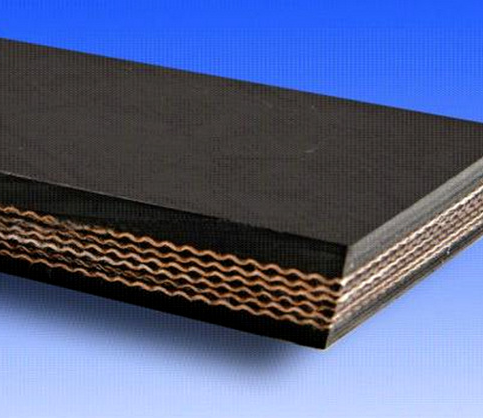

The NN conveyor belt and EP conveyor belt with the same strength grade, the NN conveyor belt is relatively thin, the yarn line is relatively tight from the section, the yarn of the EP conveyor belt has a large bending degree from the side, and the distance between the two peaks is relatively large.In addition, the NN conveyor belt body is relatively soft, and the EP is relatively stiff.

-

Can the conveyor belt be retracted again after using the elongation?

The conveyor belt will elongate during use, where-part is the elastic elongation, which can restore the original state after the external force is withdrawn, and the other part is the elongation of the skeleton material, which-part cannot be recovered.In the commonly used fabric conveyor belt, the elongation of the EP conveyor belt is relatively small, while the NN conveyor belt is relatively large, and in the process of use, the elongation ratio is increased, and because of the creep of the fiber, so the external force is much smaller than the elongation.

-

Are there any requirements for counterweight?

Normally, the counterweight is determined based on the operation of the conveyor belt, and a principle: under the premise of no slip, the lighter the better.There are many factors affecting the counterweight: reasonable and unreasonable counterweight position, active roll surface materials, wear conditions have a relatively large impact on the counterweight.

-

The conveyor belt often deviates. How to deal with it?

There are many reasons for belt deviation, such as the belt often appears deviation, check the equipment integrity, the flexibility of roller swing, roller rotation, roll surface, cleaning the material, the head and tail wheel check the parallelness of the roller, check the verticality of the weight bracket, parallelness of the weight roller, check the drop position and angle, etc. In the open conveyor belt can be installed on the conveyor.For the often running conveyor belt, increase the centering roller or install the side roller on the centering roller _, or the two ends of the two rollers before the tail wheel are alternately raised and tilted forward to help center the belt.

- A hole broke through the surface of the belt, injuring several layers of cloth, and it was repaired with cold glue or hot glue?

| Repair method | Do not repair | Natural sulcanization (cold glue) | heat cure | Replace, shorten, and add in | |

| Damage site | |||||

| Cover the glue | wear and tear | Cover covering is 1mm thick | The covering glue is less than 1mm thick | ||

| scoring | Cover within 1 / 2 of the rubber thickness | Cover thickness above 1 / 2 and length within 300mm | Cover thickness above 1 / 2 and length above 300mm | ||

| dig | Cover glue thickness within 1 / 2 and 50mm of ¢ | The glue thickness is above 1 / 2 and within 300mm of ¢ | The covering thickness is above 1 / 2 and ¢ above 300mm | ||

| Side glue | dehiscence | Within 50mm in length | Above 50mm in length | ||

| scoring | No core or steel wire is not exposed | Retain the core or steel wire | Boundless glue | ||

| core | show | Within 100mm or 1 / 2 of the number of layers | Within 100mm or over 1 / 2 of ¢ layers | ||

| break | Cut off 2 wires but not exposed | Cut off 1-2 pieces and keep the steel wire exposed | Discontent with 10% width or cut more than 3 but less than 10% of total steel wire | More damage or width above 10% of tape or 10% of total number of wire | |

| lobe | Within 500mm in length | 5001000mm | Above the top 1,000 m m | ||

The choice of conveyor belt

Choosing the suitable conveyor belt variety specifications can extend the service life of the conveyor belt, ensure the continuous stability of production, and reduce the production cost and maintenance cost.Consider several issues when selecting conveyor belts (including replacement belts):

a.Whether the variety and grain size of the material transported have changed

b.Change in maximum carrying load (peak load)

c.Whether equipment working capacity and working conditions change, there are the following options:

- Selection of skeleton material type, structure and number of layers:

a.Development direction of the conveyor belt skeleton material

The laminated conveyor belt core develops from natural fiber to synthetic fiber, from multiple layer to few layer, and from low strength, low modulus to high strength modulus mode.Cotton fiber fabric conveyor belt has been basically eliminated in foreign countries, and is gradually replaced by nylon and polyester fabric conveyor belt abroad.

In high-power transmission, a high-strength conveyor belt is needed, and the wire rope core conveyor belt is gradually replacing the once more fabric core conveyor belt.

b.Variety and properties of commonly used enhancement materials:

Table 1: Variety and properties of commonly used reinforced materials

| Enhance the variety of materials | cotton fibre | polypropylene fiber | Jinlun (N6) | Nylon (N66) | polyester fibre | glass fiber | aramid fiber | steel wire |

| Break elongation rate (100%) | 3-7 | 20-80 | 13-30 | 16-28 | 35-50 | 3-5 | 30 | 1.7-2.5 |

| wet-dry strength ratio | 110-130 | 100 | 84-92 | 85-90 | 100 | 85-90 | 90-95 | 100 |

| softening temperature (°C) | 120 °C, which turned yellow for 5 hours | 140-165 | 180 | 230-235 | 238-240 | |||

| fusion temperature | 150°C decompose | 160-177 | 215-220 | 250-260 | 235-260 | 846 | 500°C decompose | |

| heat resistance | range | range | range | same as | good people | ample | ample | ample |

| acid fastness | Cold and dilute acid resistance | fine | Weak acid resistance | Weak acid resistance | ample | same as | ample | difference |

| resistance to alkali | good people | fine | good people | good people | good people | same as | ample | good people |

| resistance to solvent | same as | same as | same as | good people | good people | good people | ample | |

| rebound degree | Extending at 2%, 74% | Extending at 3%, 96-100% | Extending at 3%, 98-100% | 100% at 4% | 95-100% | 100% | 100% | 100% |

c.Characteristics of enhanced materials and main application: see Table 2

Table 2: Characteristics and main uses of various enhancement materials

| Material name | code name | performance characteristics | Main delivery materials and working conditions |

| druid | CC | Low strength, hygroscopic, not corrosion, fatigue resistance is poor, thick body, heavy belt body | Things with less loose density and less wear Materials, such as grain, fiber, wood shoes, waste sand, coal chips, cement, etc., and materials with a material temperature not exceeding 150°C |

| Cleaning cotton canvas | TC | The strength is higher than cotton canvas, thin thickness, relatively light. | |

| JinLun canvas | NN | High strength, impact resistance, yield, good groove formation and large use elongation rate | Loose density of various granularity Ore, large impact, strict wear Heavy on various materials, and CC, TC Normal temperature material achievable to be carried by the conveyor belt |

| Polyester canvas | PP | High modulus, small elongation rate, high strength, bending resistance, fatigue resistance, various media, poor groove | |

| Cleaning cotton canvas | EP | High modulus, good groove formation, bending resistance, fatigue resistance, medium resistance | |

| High model low Dietary cotton canvas |

EP-TNG | 1. The same EP. 2. Good groove 3. Excellent size stability |

1. With the NN conveyor belt. 2. High delivery temperature (the highest can be Material of up to 450C) 3. Suitable for conveyor lines with particularly high size requirements, and can be replaced with steel rope conveyor belt |

| glass cloth | GG | The paper has high modulus, poor flexure, small elongation rate, good high temperature resistance and poor adhesion performance | 1. Transfer materials with high temperature 2. For the conveyor belt with more dimension requirements 3. Not suitable for carrying impulse I with large performance The material |

| Fang Lun weaving thing |

AA | High strength, high modulus, excellent temperature resistance, good size stability. | Various materials can be delivered |

| wirerope | ST | High strength, high modulus, good size stability, poor corrosion resistance, special treatment and the design of reasonable formula for adhesion to rubber | Used for high power, long distance, high strength Degree conveyor belt.Comparof tear prevention performance difference |

d.Selection of band core layers

The number of core layers has strict requirements on the true diameter of the conveyor belt wheel. The belt diameter is too small, the yield and yield of the conveyor belt increases after the belt wheel steering, the fatigue wear of covering glue increases, the fatigue degree of enhanced materials, core layer rubber and coating glue also increases, and the service life of the conveyor belt is shortened.

Usually the pulley diameter D has the following requirements:

Cotton Canvas Belt D 80s (in mm)

Nylon Band with D 90s

EP band with D 108s

Wire rope center strap D 145s

The s: band core thickness or wire rope diameter

If the diameter of the belt pulley is small and cannot be changed, the enhancement material with a higher strength level can be selected as the belt core, with the layers of the sincere small belt core canvas, so that the conveyor belt and the belt wheel can cooperate better.

In general, the number of conveyor belt should not exceed 6 layers and EP conveyor should not exceed 5 layers.

- Selection of covering rubber varieties and thickness:

Because the service life of the conveyor belt is closely related to the covering belt, and the use of the conveyor belt will end with large wear, aging and damage. Therefore, choosing the appropriate type and original covering belt can make the covering rubber have a comparable service life with the belt core and give full play to the value of the conveyor belt.

Table 3 Type and use of covering glue

| Yang burning | For conveying materials with fire hazards or inaccessible workplace |

| common | Materials with less wear: such as coal, grain, cement, sand failure, coke carbon, etc. |

| abrasion resistant. | Ore, limestone, coke carbon, slag |

| Anti-tear | Compared to the major ore, the strong impact of the ore, broken glass |

| Heat resistant / high temperature resistant | Cement clinker, sintering ore and various materials with higher temperature |

| oil proof | Pine, food, and oil on the surface |

| acid and alkali resistant | Fertilizer lime, etc |

| cold-resistant | Use the conveyor belt of dry and low temperature materials and in low temperature and cold areas |

| Heat resistance and wear resistance | Transportation of high temperature materials with large dry delivery and for reversible 1. condition |

I appreciate you showing how the conveyor belt works and the solution. I’ve been hunting for the same information for a number of days, and I’ve finally discovered it. superb work

Thanks

we are happy to share our idea , any suggestion we are appreciated .