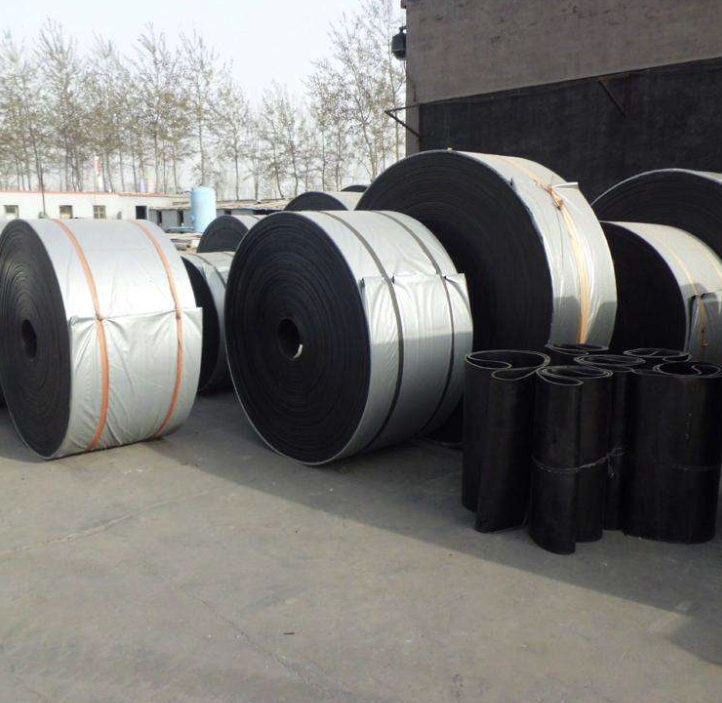

EP rubber conveyor belt

Also known as ordinary cotton canvas conveyor belt, suitable for short distance, medium load conditions conveying materials, tensile is relatively low, bearing has certain restrictions.

Product characteristics

- The product is refined by whole cotton canvas (CC) or vitamin cotton interwoven adhesive canvas (VC) through pressure extension, molding, vulcanization and other processes.

- The product conforms to the requirements of different use conditions, and can be made into different structures such as package edge type, open edge type, middle ladder type and edge ladder type

specifications

(1) Core material: polyester cotton interwoven cloth TC-70 type, full cotton canvas CC-56 type

(2) Bandwidth: 300mm-3,000 m m

(3) Cloth layer: 1-12 layers

(4) Cover rubber thickness: working face: 1.5-10mm non-working face: 0mm-6mm.

This conveyor belt is core as fiber fabric, general rubber as covering material with a smooth surface (Figure 1. The band core is a layered or integral fabric woven from fibers such as cotton, nylon, polyester, or Vinylon.Cotton fiber is the earliest applied core material, easy to adhere to rubber, wet state strength is slightly improved, but the low breaking strength is mostly about 56 cattle / (mm / layer)), anti-corrosion and mildew prevention is poor, the use is decreasing.Use nylon fabric in the late 1950s and has become one of the largest quantities.Nylon fiber strength up to 700 N / (mm · layer), water resistant, corrosion resistant, bending and fatigue resistant; but the elastic extension is large.The Polyester fiber has similar properties to the nylon fiber, and the elastic elongation is only half that of the nylon fiber, which is a promising material.The strength of vinilylon fiber is 200 cattle / (mm · layer), the elastic elongation is smaller than nylon fiber, easy to adhere to rubber, and good heat resistance, but the strength should be reduced by 10~25% in wet state, only used in a few countries such as China and Japan.Only one fiber can be used or two fibers.

- Ordinary conveyor belt is widely used in building materials, chemical, coal, power, metallurgy and other departments, suitable for conveying non-corrosive spike-free block, granular, powder, such as materials, coal, coke, sand, cement and other bulk (material) or adult items, the delivery of accumulation density of 6.5~2.5t/m3 block, granular, powder and other loose materials, can also be used for adult goods delivery.

EP conveyor belt is divided into many specifications and models according to the service environment and requirements:

- According to the size of the transportation volume, it is divided into: B300 B400 B500 B600 B650 B800 B1000 B1200 B1400 B1600B1800 B2000 and other common models (B represents the width, in mm).

- According to the different use environment, it can be divided into: heat resistance conveyor belt, cold resistance conveyor belt, acid and alkali resistance conveyor belt, oil resistance conveyor belt, food conveyor belt and other models.The minimum thickness of ordinary conveyor belt and food conveyor belt is 3.0mm, and the minimum thickness of heat resistant conveyor belt, cold resistant conveyor belt, acid resistant conveyor belt and oil resistant conveyor belt is 4.5mm and 2.0mm.The thickness of the coating glue can be increased by 1.5mm according to the details of the use environment.

supplementary information:

Ordinary conveyor belt of new material should also adapt to high temperature resistance and low temperature performance: can operate continuously in the temperature range of-73℃ ~ + 260℃; good resistance to other chemical substances; good electrical performance: good insulation performance, high insulation layer resistance wear strength; good peeling: anti-adhesion, small friction coefficient, smooth surface; good size stability: new ordinary conveyor belt, stable in size and easy deformation in high temperature and high pressure environment.

Implementation of the standard: GB / T7984-2001

Overlayer: tensile strength not less than 15Mpa, pull extension length not less than 350%, grinding consumption 200mm3, average layer of longitudinal test strength shall not be less than 3.2 N/mm, and between covering glue and cloth shall not be less than 2.1 N/mm.

The use of the conveyor belt can be divided into:

Oil, skid, climbing, acid, base, heat, cold, flame, corrosion, moisture, low temperature, oil, heat, cold, low temperature, acid, and flame resistance.

Connection method

All the conveyor belts must be annular for use, so the quality of the conveyor belt joints will directly affect the service life of the conveyor belt and the smooth operation of the conveyor line.Common methods include mechanical joints, cold bonding joints, hot sulfur joints, etc.

Mechanical joint method

Generally refers to the use of belt buckle joint, this joint method is convenient and convenient, but also more economical, but the efficiency of the joint is low, easy to damage, which has a certain impact on the service life of the conveyor belt products.For Pvc and PVG, below grade 8 products.

Cold adhesive head method

That is, the cold adhesive is used to make the joint.This joint method is more efficient than the mechanical joint, and should be able to have a better joint effect, but in practice, because the process conditions are more difficult to master, in addition, the quality of the adhesive has a great impact on the joint, so it is not very stable.

Heat sulfide joint method

Practice has proved to be the best joint method, can ensure high joint efficiency, but also very stable, the joint life is also very long, easy to master.However, there are the disadvantages of process trouble, high cost and long joint time.

The longitudinal pull elongation rate of full thickness shall not be less than 10%, and the longitudinal reference force elongation rate of full thickness is not greater than 1.5%

Technical specifications for joint

Connectors can be connected by plate sulcanization to ensure the pressure and temperature required for vulcanization or melting. There are various structural forms of joints, depending on the structure of the belt, for heat resistance, cold resistance, oil resistance, acid resistance, alkali resistance, the corresponding bonding method, or absolutely dry, clean, dust free, no exposure, for moisture, water vapor must be removed to meet joint requirements if necessary.

Product characteristics

- The conveyor belt is made of whole cotton canvas (CC) or dimensional cotton woven pulp canvas (VC) by extension, molding, sulphization etc.2. The conveyor belt products are suitable for conveying non-corrosive block, granular, powder of various materials, such as coal, coke, sand, cement and other materials (materials) or adult articles at room temperature.3. The conveyor belt products meet the requirements of different use conditions, and can be made into different structures such as wrapped edge conveyor belt, open edge type contraction belt, middle ladder type conveyor belt, edge ladder conveyor belt and edge ladder type conveyor belt.

Cotton cleansing canvas material

All-cotton canvas structure is woven by cotton fiber in both direction and latitude, with low elongation rate and good adhesion.Under high temperature conditions, the deformation is small, suitable for short distance, conveyor belt is used by cotton conveyor belt quality upgrade products, its tensile body using mixed dimension and latitude cotton fiber interwoven, performance is better than cotton conveyor belt, especially the belt is thinner, lighter, impact resistance is greatly improved.Suitable for conveying materials with short distance and medium load conditions.3. According to the coating properties, the varieties are divided into ordinary, heat resistant, refractory, burning resistant, acid and alkali resistant, oil resistant, etc.4. Specification (1) Core material: polyester cotton interwoven fabric TC-70 type, full cotton canvas CC-56 type (2) Bandwidth: 100mm-1600mm (3) fabric layer: 1-10 layer (4) coating rubber: working face: 1.5-9mm non-working face: 0mm-4.5mm.

Transport belt storage

- conveyor belt in transportation and storage?It should be kept clean?Avoid direct sunlight?Rain and snow immersion?Prevention with acid, alkali and oil?Organic solvents and other substances that affect the rubber quality are in contact?And it is about 1 meter away from the heating device.2. The temperature in the warehouse should be kept between-15℃ and + 40℃?The relative humidity should be maintained between 50-80%.3. The conveyor belt shall be placed in volume in storage?Do not fold?It shall be flipped quarterly during placement.4. The operation speed of the conveyor belt shall not be greater than 5.0 m / second?Large transportation block degree?Materials with large wear and fixed plough unloading device shall be as low as possible.When the specified speed is exceeded?Can affect the service life of the adhesive tape.

Leave a Reply

Want to join the discussion?Feel free to contribute!