How To choose conveyor belt

How to choose the right conveyor belt?

With the development of industry, machinery is also constantly optimized, the conveyor belt manufacturers on the market are also increasing, which for customers, advantages and disadvantages, the good aspect is to choose more, the bad place is more to dazzling, do not know which good to choose, easy to choose wrong. The conveyor beltmanufacturer Qingdao Jahung Conveyor belt Co.,ltd analyze, how to choose the appropriate conveyor belt.

- Selection of the conveyor belt core material and the structure of the conveyor belt: the performance of the conveyor belt is greatly related to the core material, the structure and the number of layers. Cotton canvas multi-layer conveyor belt has the characteristics of low strength, many layers, fatigue resistance and corrosion resistance. Light weight, high energy consumption, nylon conveyor belt high strength, high elasticity, light weight, good impact resistance, bending resistance, good groove performance, mildew resistance, water resistance than cotton canvas frame long the disadvantages are that the elongation of the belt is large. Use nylon rubber bands when the tension trip can be set longer. The strength of the polyester band is similar to that of the cotton band. It has the advantage of a nylon band, with a higher elastic modulus than nylon. Small elongation rate, good dimensional stability. It is the ideal conveyor belt commonly used in industry. High strength, good groove performance, small elongation rate, short tension trip, especially suitable for large batch transportation. High belt speed, long-distance conveying requirements

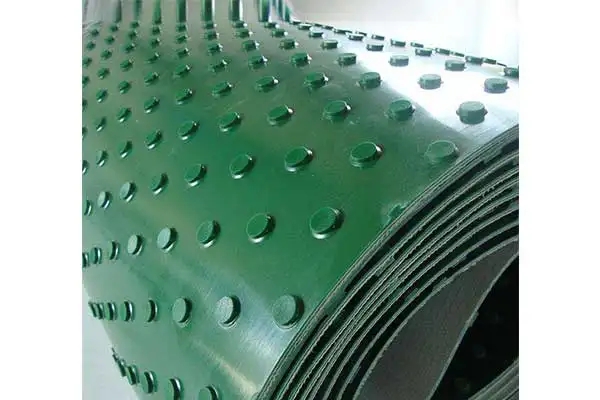

- Selection of overlayer: The selection of overlayer includes covering material, surface shape and thickness. The main ingredients of the coating are various rubber and plastics. In most climates, the rubber belt has a tilt angle of no more than a straight angle. Flame retardant conveyor belt works normally with an inclination of less than 120 degrees. Although the main frame material is not as good as rubber, it has good flame retardant, unloading and cleaning properties. Because the performance of various rubber is also very different, such as natural rubber, rubber butadiene rubber with good absorption capacity and wear resistance, especially ethylene propylene rubber heat resistance, nitrile rubber with good oil resistance, butyl rubber heat resistance. Oxidation resistance chemistry, so we must be based on the type of common materials, operating conditions and working environment to cover the type of material selection;

- Increasing the thickness of the additional overlayer is also beneficial to improve the impact resistance and wear resistance of the rubber conveyor belt. In particular, the cotton core has been replaced by the synthetic fiber core, and the core is designed to greatly improve the performance and increase the thickness of the coating, which has to increase the overall resistance of the belt.

We first have to use the tokun or the tray according to the weight of the material transported and the conveyor, and then choose the conveyor belt of the matching strength. The thickness of the body, tensile strength, the thickness of the cloth layer, we should consider the thickness of the body match in the design. Then there is the color requirement of the conveyor belt, because we know that some industries have a requirement for the color requirement of the conveyor belt, such as the food processing industry is mainly white. If the material we deliver needs to rise on the slope, we choose specially processed conveyor belts, such as custom baffle, skirts or guides. Conveor belt in the work of environmental requirements, we can choose whether cold and heat, oil or acid and alkali resistance, to choose the corresponding conveyor belt material.

According to the diameter of the drum on the conveyor, we can also choose whether the conveyor belt get thickness is appropriate, or choose the corresponding drum according to the conveyor belt.

Industrial belt materials can be divided into PVC (polyvinyl chloride), PU (polyurethane), PE (polyolefin), Si (silicone). Let’s do some analysis of the advantages and disadvantages of these conventional materials.

I, PVC (PVC)

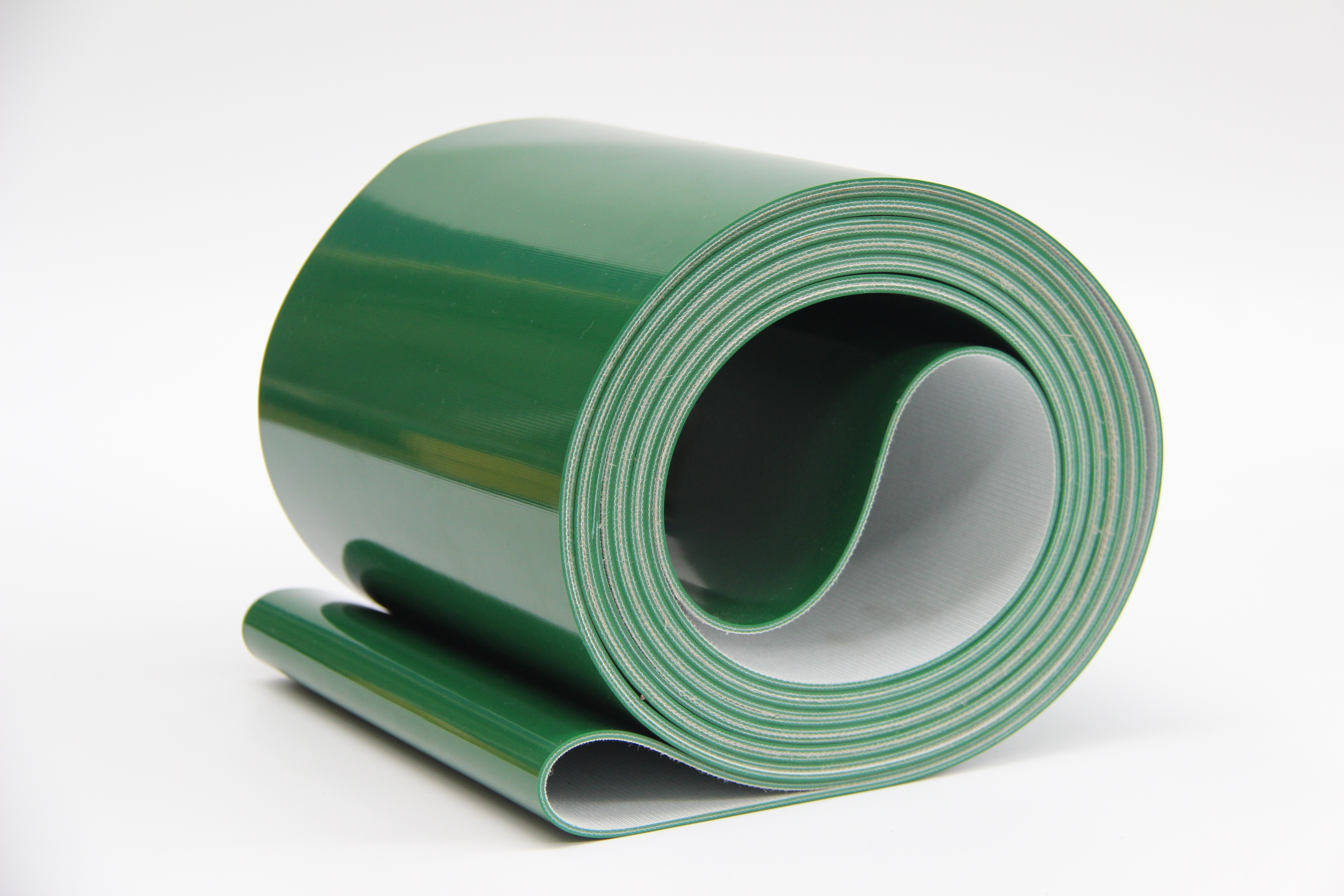

PVC conveyor belt

- Economic and applicable, the price of the conveyor belt in the actual use process to consider the use cost, so to take into account the economy;

- Easy to process, PVC is in the processing process is relatively easy to process, good plasticity;

- Acid and alkali resistance, PVC chemical stability, and a certain ability to resist weak acid and weak alkali.

shortcoming:

- Low hardness is not wear resistance, and the wear resistance of PVC conveyor belt is not good during use, which is the reason why some equipment needs to use PU for type selection;

- Poor oil resistance, and the PVC conveyor belt should not be used in food machinery and other places with edible oil or mechanical oil.

II, PU (polyurethane)

PU conveyor belt

merit:

- High hardness and wear resistance. The surface hardness of the PU conveyor belt can reach 80-90, which has the advantages of wear resistance and cutting resistance;

- Good oil resistance, and the PU conveyor belt is particularly widely used in the food industry, edible oil and mechanical oil will not have a great impact on its service life;

- The roller is good, which means that the drum rarely occurs in the use of the conveyor belt;

4, Food grade, PU conveyor belt is widely used in food because of its characteristics, pasta machinery, fried food, and so on.

shortcoming:

- Expensive. Compared to the PVC conveyor belt, the price of the PU conveyor belt is relatively expensive, so the production cost may be taken into account in the type selection;

- Acid and alkali resistance is weak, and the PU conveyor zone is relatively weak compared to the PVC transport belt

III, PE (polyolefin)

PE conveyor belt

merit:

- Food grade, which is a selling point of the PE belt, it is absolutely in line with the food grade, the combustion produces water and CO2;

- Good pyrolysis resistance, stable chemical properties and good heat resistance;

- Decomposition is non-toxic, and PE decomposition is not only non-toxic, but also relatively easy to decompose.

shortcoming:

- Low hardness and wear-resistant, PE belt is mostly used in food industry and pharmaceutical industry, and should not be used in other industries;

- Poor oil resistance, acid and alkalinity. It is best not to use the equipment with edible oil and mechanical oil

IV, Si (silicone)

silicon conveyor belt

merit:

- Food grade, this feature is an important reason for its use in the food industry;

- High temperature resistance, and the conventional silicone tape can withstand the high temperature of 100-500 degrees, with stable chemical properties

- Anti-sticky, silicone tape non-stick sugar, chocolate and other foods with high sugar content.

shortcoming:

- Expensive, silicone tape is expensive compared to ordinary conveyor belt;

- The hardness is low, so some of the conveyor belts in the oven mostly use Teflon mesh belt / cloth;

- Poor overroll, silicone belt has no lateral stability, the material is relatively soft.

Leave a Reply

Want to join the discussion?Feel free to contribute!