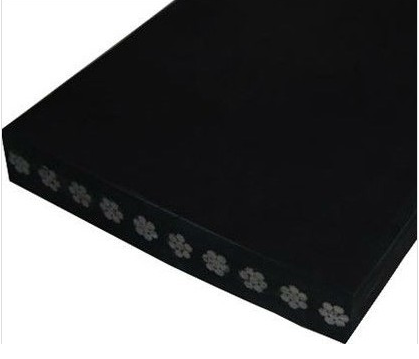

Performance description: the wire rope core conveyor belt skeleton material is made of high strength wire rope, after cold pressure molding and cover glue, after the vulcanization process.

Application location: main conveying line, long distance transportation, roadway conveying, loading machine, inclined conveying, other demanding requirements.

Tensile strength: 630 ~ 7500 N/mm Width: 650~2400mm.

Conveyor belt features and advantages:

-

Use galvanized open steel wire rope

Galvanized open steel wire rope is selected to meet various special needs. The wire rope has high elasticity and low elongation, and can also get high joint efficiency. Galvanized wire rope can be closely bonded with the core glue to form a protective layer against corrosion.

-

High strength

Qingdao Jahung steel wire rope core conveyor belt can meet the most customer application requirements, continuous research and development of higher strength conveyor belt, to meet the long transport distance transport system.

-

Reduce the tension of the travel trip

The elongation of Qingdao Juhang rope core is 0.25%, which can reduce the cost of tension system in many applications. This is preferred in transport situations with a long range or low elongation.

4, longer joint life

After the experiment in the dynamic joint testing machine proves that when the dynamic joint efficiency of Qingdao Juhang wire rope core conveyor belt exceeds 50% of the rated strength, the joint can reach the same service life as the belt according to the test method of DIN22131-3 part.

5. High impact resistance

Our cover glue is more closely bonded to provide good impact resistance and tear resistance.

-

Lower unit transportation costs

Less conveyors and joints, shorter tension travel and reduced conveyor belt inventory are all greater savings in investment costs. Longer conveyor belt and joints reduce downtime and reduce unit transportation costs.

Use: it can be widely used in coal, mining, port, metallurgy, electric power, chemical industry and other fields of material transportation.

Variety: according to the performance of covering glue, it can be divided into ordinary, flame retardant, cold resistant, wear resistant, heat resistant, acid and alkali resistant varieties.

According to the internal structure, it can be divided into: ordinary structure type, transverse enhanced tear prevention type.

| MT668-2019 | |||||||||||||||

| TYPE | ST/S630 | ST/S800 | ST/S1000 | ST/1250 | ST/S1600 | ST/S2000 | ST/S2500 | ST/S2800 | ST/S3150 | ST/S3500 | ST/S4000 | ST/S4500 | ST/S5000 | ST/S5400 | ST/S6300 |

| Longitudinal tensile strength N/mm | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 2800 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 | 6300 |

| Steel wire max diameter(mm) | 3.0 | 3.3 | 4.0 | 4.3 | 5.0 | 6.0 | 7.2 | 7.5 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 | 11.3 | 12.8 |

| Steel wire distance(mm) | 11 | 11 | 14 | 14 | 14 | 14 | 16.5 | 16.5 | 16.5 | 16.5 | 16.5 | 17 | 18.5 | 18.5 | 20 |

| Upper rubber cover(mm) | 5 | 5 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8.5 | 9 | 10 |

| Bottom rubber cover(mm) | 4 | 4 | 4 | 4 | 4 | 4 | 5 | 5 | 5.5 | 6 | 6.5 | 7 | 7.5 | 8 | 10 |

| Belt width (mm) | Min quantity of steel wire | ||||||||||||||

| 800 | 66 | 66 | 55 | 55 | 55 | 55 | 46 | 46 | 46 | 46 | |||||

| 1000 | 86 | 86 | 72 | 72 | 72 | 72 | 58 | 58 | 58 | 58 | 62 | 57 | 52 | 52 | 48 |

| 1200 | 106 | 106 | 88 | 88 | 88 | 88 | 71 | 71 | 71 | 71 | 74 | 68 | 63 | 63 | 57 |

| 1400 | 126 | 126 | 105 | 105 | 105 | 105 | 84 | 84 | 84 | 84 | 87 | 80 | 74 | 74 | 67 |

| 1600 | 146 | 146 | 122 | 122 | 122 | 122 | 98 | 98 | 98 | 98 | 99 | 93 | 86 | 86 | 76 |

| 1800 | 166 | 166 | 138 | 138 | 138 | 138 | 111 | 111 | 111 | 111 | 111 | 104 | 98 | 98 | 86 |

| 2000 | 186 | 186 | 155 | 155 | 155 | 155 | 124 | 124 | 124 | 124 | 124 | 116 | 110 | 110 | 96 |

| 2200 | 206 | 206 | 172 | 172 | 172 | 172 | 138 | 138 | 138 | 138 | 138 | 129 | 121 | 121 | 106 |

| 2400 | 226 | 226 | 188 | 188 | 188 | 188 | 151 | 151 | 151 | 151 | 151 | 141 | 133 | 133 | 116 |