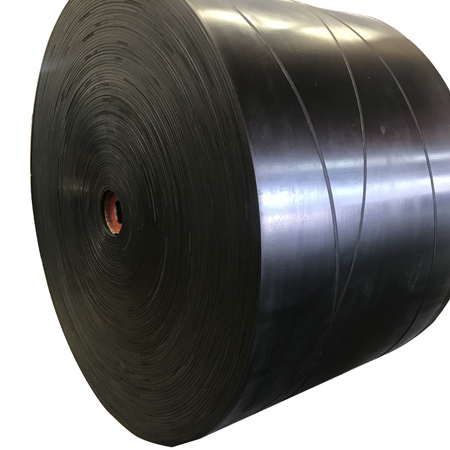

Heat Resistance Conveyor Belt

Heat resistance conveyor belt is made of multi-layer rubber cotton canvas (polyester cotton) or polyester canvas covered with high temperature or heat resistant rubber; Vulcanized by high temperature bonding, suitable for conveying hot coke, cement, slag and hot castings below 175℃. Mainly used in metallurgy, construction and other industries, conveying sinter, coke, cement clinker and other high-temperature materials, the material temperature does not exceed 800℃, belt surface temperature does not exceed 220℃ conditions for use.

Models

Heat resistant conveyor belts fall into three models.

Mode1: able to with stand the test temperature of less than 100°C, code S1;

Mode2: able to with stand the test temperature of less than 125°C, code S2;

Mode3: able to with stand the test temperature of less than 150°C, code S3;

Mode4: able to with stand the test temperature of less than 175°C, code S4;

Physical Performance

| Index | Model | ||||

| Model1 | Model2 | Model3 | Model4 | ||

| Variation range | |||||

| Hardness | Difference after and before aging(IRHD) | 20 | ±20 | ±20 | |

| Maxmum after aging(IRHD) | 85 | ||||

| Tensile strength | Decrease of performance variance rate %<= | -25 | -30 | -40 | -40 |

| Maxmum after aging Mpa | 12 | 10 | 5 | 5 | |

| elongation at break | Performance variance rate % | -50 | -55 | -55 | |

| Maxmum after aging % | 200 | 180 | 180 | ||

Adhesion of Inter Layer

| Index | Between faberic layers | Between cover layer and belt core | |

| Cover layer thickness 0.8-1.5mm | Cover layer thickness>1.5mm | ||

| Average of all test samples,N/mm no less than | 3 | 2.2 | 2.6 |

| The lowest data of all test samples,N/mm,no less than | 2 | 1.6 | 2 |

Related Products

Shot Blasting Conveyor Belt

Flame Retardant Conveyor Belt/PVG Solid Woven Conveyor Belts

Nylon conveyor belt