PVG/PVC whole core flame retardant conveyor belts manufacturers

We are professional PVG/PVC Solid Woven flame retardant conveyor belt manufacturer .we have make PVG/PVC whole core flame retardant conveyor belt 30 years .

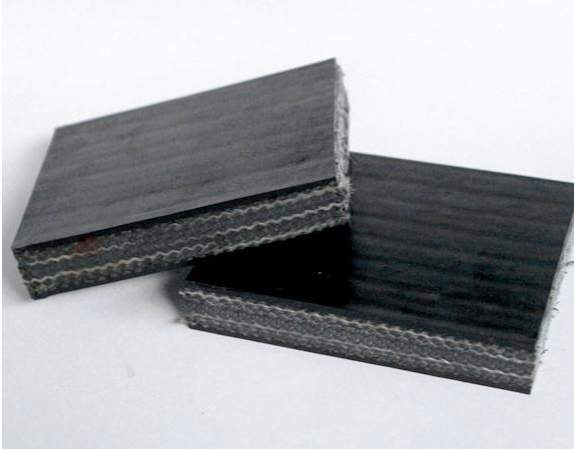

Flame-retardant conveyor belts are mainly used underground in coal mines.Its characteristics are: the body does not decayer, elongation, impact resistance, tear resistance.According to different structure, it can be divided into PVC type (plastic surface), PVG type (with rubber surface on PVC basis) whole core flame retardant belt, implement MT914-2002 standard.

The PVG flame retardant conveyor belt is suitable for the delivery of wet water material inclination below 20 degrees.The Pvc flame retardant conveyor is suitable for material delivery at dry inclination below 16 degrees.

PVG flame retardant conveyor belt is not peeling, impact resistant, elongation resistant, and tear resistant.According to different structures, it can be divided into PVC as type, (plastic surface) PVG type (flame retardant conveyor belt, coal mine conveyor belt), and implement MT / 914-2008 standard.

The band is not peeling, impact resistant, elongation resistant, and tear resistant.According to different structures, it can be divided into PVC type, (plastic surface) PVG type (with rubber surface to PVC basis) whole core flame retardant belt, and implement MT / 914-2002 standard.

Type Pvc is suitable for material delivery under dry conditions with an inclination below 16 degrees.

PVG is suitable for wet water material below 20 degrees.

Performance Introduction:

Safety performance:

The flame retardant conveyor belt has passed the flame retardant test and static electricity test, and has obtained the qualified coal safety mark and customer approval.

mechanical behavior:

The flame retardant conveyor belt has excellent mechanical performance, which can provide users with the longest service life and economic installation and use.

Maximum service life: the service life of band is determined by the following factors, woven by warp and latitude filament and covered cotton spinning; special formula PVC achieves extremely high bond strength between core and cover; special formula coating; thus make the band resistant to impact, tear and wear resistance.

Flame retardant conveyor belt has the whole core flame resistance belt wear resistance, static resistance, waterproof, flame resistance, high strength, excellent safety performance and compared with other flame retardant conveyor belt with lower cost, lower price, is one of the more domestic and popular flame retardant conveyor varieties, especially suitable for coal mine and other underground slope conveying places.

Product structure: the flame retardant conveyor belt uses the overall band core as the skeleton material, and is molded by the PVC material with excellent static resistance and flame retardant properties.

Connector performance:

The flame retardant conveyor belt is connected by mechanical buckle, and its joint strength can reach 50% -90% of the rated tensile strength, and the sulfur joint can reach 60% -90% of the rated tensile strength.Various forms of joints can meet the different needs of customers and ensure the safe and efficient operation of the system.

Resistant energy:

Roller friction: the roller surface temperature is not more than 325℃.

Spray lamp combustion: the average flame time of full-thickness test parts shall not be greater than 3.0S, and the average decoverslip shall not be no greater than 5.0S.

Propane combustion: nondestructive length greater than 250mm.

Surface resistance value: upper and below average value not greater than 3.010.

Principle of flame retardant

Natural rubber and butobenzene rubber are flammable, and flame retardant should be added to achieve the refractory purpose.The layered refractory PVG conveyor belt adhesive flame retardant system adopts antimony trioxide, chlorine fossil paraffin, zinc borate, and aluminum hydroxide.The effect is as follows: antimony trioxide: flame retardant, used alone without flame retardant effect, but with chlorine-containing compounds when using to show a strong flame retardant effect.When combustion, antimony trioxide reacts with chloride-containing compounds in the combustible surface layer to generate volatile antimony chloride and antimony chloride oxide.Their volatiles absorb heat and the gas separates oxygen from dilute combustible.Chlorine paraffin: flame retardant, under high temperature decomposition of chlorine fossil wax chlorine atoms, chlorine atoms and polymer (rubber, nylon canvas, etc.) reaction to generate hydrogen chloride, hydrogen chloride and high active hydroxyl radical or hydrogen atoms reaction to generate water or hydrogen, thus interrupt the chain oxidation process, make combustion down, and stop, by adding flame retardant and carbon black to meet the requirements of difficult combustion.

Model type and technical parameters of PVG conveyor belt

| Product execution standard MT914-2002 BS3289 HG2805 | Selection safety factor 10 (pull-off strength * 1 / 10) | |||||

| Transportation inclination Angle | ||||||

| Standard model | Corresponding level | Pull-off strength, N/mm | Pull-off elongation rate,% | Minimum transmission drum diameter is recommended | ||

| direction | broadwise | direction | broadwise | |||

| 680S | level Four | 680 | 265 | 15 | 18 | 400 |

| 800S | Pyatyi | 800 | 280 | 500 | ||

| 1000S | sixth class | 1000 | 300 | 630 | ||

| 1250S | Level 7 | 1250 | 350 | 750 | ||

| 1400S | Level 8 | 1400 | 350 | 750 | ||

Safety performance:

| Performance name | Alcohol burning | Propane combustion | conductive performance | Roller friction |

| standard value | Meverage 3S, single value 10S (with glue) | ≥250mm | ≤3X10Ω | ≤325℃ |

| Meverage 5S, single value 15S (sealless) | No Mars |

Leave a Reply

Want to join the discussion?Feel free to contribute!