15 Reasons and adjustment methods of belt conveyor tape deviation

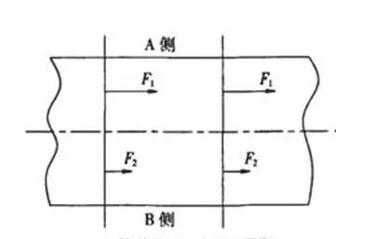

The fundamental cause of the belt deviation is that the external force of the tape in the belt width direction is not zero, or the tensile stress perpendicular to the width direction of the belt is uneven, which leads to the reverse force of the belt, which shifts the belt to one side.Common running bias phenomena are as follows.

1. The belt deviation caused by the center of the head, tail and middle frame is not in a straight line.

This situation is usually due to the installation.Since the center of these three is not in a straight line, the longitudinal centerline of the belt is not perpendicular to the drum shaft line, thus causing the belt machine to deviate in operation.

02 The installation position of the roller is not properly causing the deviation of the belt at the roller.

A belt conveyor has multiple rollers, all rollers must be installed perpendicular to the centerline of the tape and parallel to the horizontal surface. If the mounting force of the roller is not enough, or one end of the roller in the rear is at the front end and the longitudinal center line of the tape is not vertical to the horizontal surface, the joint force of the belt in the direction of the belt.

03 The conveyor belt joint is incorrect, causing the central deviation of the conveyor belt.

Commonused belt joints have two forms: mechanical and sulfide joints.Either way, the joint is required to be flat. If the joint is not correct, the tension on both sides of the belt will be inconsistent and thus deviate in operation.The running deviation caused by the wrong tape joint is the running deviation where the tape joint runs.

04 Belt deviation caused by improper roller holder or loose bolts fixing the roller holder.

The symmetry of the roller set center line to the conveyor rack center line shall not be greater than 3.0mm, and the upper surface of the roller shall be located on the same horizontal or inclined surface.If the mounting error is too large or the fastening bolt is loose, the belt will deviate.

05 Belt deviation caused by conveyor belt damage.

The conveyor belt is prone to damage during operation. When the damage degree on both sides of the center line of the conveyor belt is different, the stretching rate on both sides often changes. When due to the large difference in the stretching rate on both sides, the elongation of the belt on both sides is inconsistent, it is easy to cause belt deviation.

06 Belt deviation caused by the material unloading point that is not in the middle of the conveyor belt.

When the material unloading point is not in the middle of the tape, the uneven difference of the tape force along the two sides of the longitudinal centerline directly causes the deviation of the conveyor belt in operation.If the conveyor belt does not deviate during empty load, and always runs away to one side during heavy load, the conveyor belt has shown a partial load.The position of the hopper or conveyor shall be adjusted to load the conveyor belt to prevent deviation.

07 Belt running deviation caused by the lower material impact.

When the material falls on the belt, due to the gravity and inertia of the material, it may cause the belt deviation.

08 Belt deviation caused by accumulated materials on rollers and rollers.

For iron powder and other materials with a certain viscosity, after the scattered unevenly stuck to the roller and roller, making the roller or roller locally become uneven, due to uneven tension and running deviation.After running in the deviation of the material phenomenon is more serious, causing a vicious circle.The probability of such a failure is greater in wet weather and harbour operations.Therefore, the sweeper of the adhesive tape should ensure the normal operation.

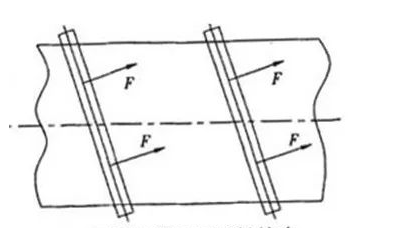

09 The roller mounting angle is not accurate enough to cause the deviation of the belt.

If the error of the center line of the bearing belt machine and the roller installation position is large, the belt will be subject to lateral force in operation, causing the belt to deviate to the side of the bearing section.If the installation position of the reversing roller and roller set is not correct, both the return section and the carrying section, the lighter, and will gradually return to the center line of the frame.However, if the drive roller tilt, the running deviation will become more and more serious.

10 Belt running deviation caused by unqualified belt quality.

The belt core density is uneven, and the force along the bandwidth direction is uneven. Under the action of tension, the elongation in the belt operation is inconsistent, causing the belt deviation.If the uneven belt density is caused by the system failure of the production equipment, with a certain regularity, then the direction of the deviation will also show a certain regularity.

11 Belt deviation caused by installation and commissioning error of belt tensioning device.

Due to the poor operator skills, weak responsibility and not strict acceptance in the installation and commissioning process, the belt tensioning device is not working normally, with different tension degree on both sides of the belt and uneven force caused by belt deviation.

12 Long-term use causes aging, deformation and belt deviation.

After a period of belt use, the relaxation phenomenon will occur, resulting in uneven stress distribution in the belt, thus increasing the opportunity of belt deviation.

13 Belt running deviation caused by rack tilt.

If the centerline of the frame is tilted and the left and right sides of the rack are tilted horizontally, the belt may receive a certain lateral pull and pull the belt to a certain side.

14 Belt running deviation caused by serious equipment vibration.

During the operation of the belt, the violent vibration of the belt machine equipment will also cause the belt running deviation, especially the roller radial running belt running deviation is the most obvious.

15 Belt deviation caused by the too small radius of curvature of the concave section belt conveyor.

For the belt conveyor designed with a concave section, such as the radius of curvature of the concave section is too small, if there is no material on the belt when starting, the belt will bounce up in the concave section, and the belt will be blown biased in windy weather.

2. Adjustment measures for belt running deviation

Through the above analysis of the belt deviation, the following measures are taken.

1) Adjust the head, tail and middle frame of the belt machine so that the center of the three is on the same straight line.

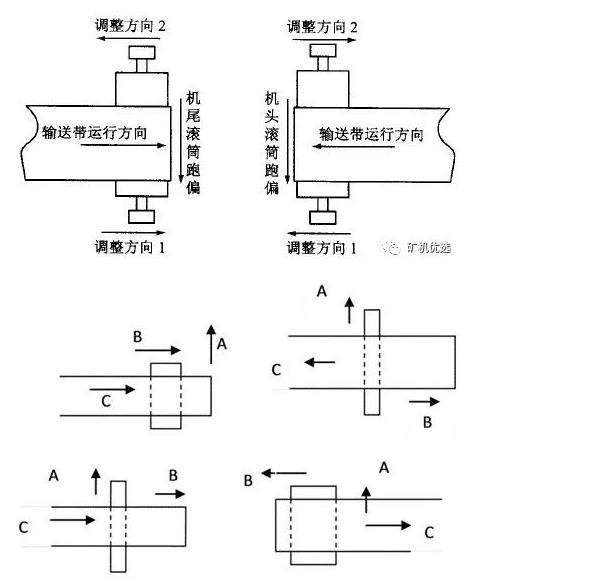

2) Adjust the roller installation position so that the roller shaft line is perpendicular to the vertical centerline of the tape and parallel to the horizontal surface.Take the first wheel drum as an example, if the tape runs off to which side bearing seat, move the bearing seat to the tape or the opposite direction.However, it should be noted that the actual offset of the center line and the center line of the tape must be determined before the adjustment to ensure the correct position of the adjusted roller.

3) Cut off the improper tape joint and redo the belt connector.Keep the joint straight and the linear tolerance over 10m length not greater than 20mm.In addition, the nailed belt buckle should best be segmented with the length of the groove roller, so as to ensure the groove performance at the tape joint, prevent and reduce the pin break, and avoid the tear tape accident.

4) The deviation caused by the roller holder is not correct can move the roller holder to the forward direction of the tape. Generally, moving a few rollers can correct the deviation.When the deviation is serious, the roll holder needs to be recorrected so that the horizontal error of the roll group is controlled within the allowable deviation.If the belt deviation is caused by the loose bolts of the fixed roller holder, retighten the loose bolts can be solved.

5) It can be solved by strengthening the inspection and maintenance of the belt, and repairing or replacing the damaged belt in time.

6) Adjust the unloading point position to be located in the middle of the tape.

7) Use a reasonable structure guide plate to avoid large blocks or large height direct feeding, and several sets of buffer rollers can also be installed under the feeding port.

8) Remove the roller or roller surface can be eliminated.At the same time, the empty section spring cleaner should be adjusted, and the contact length between the cleaner and the conveyor belt in the drum shaft direction should be greater than 85% of the bandwidth, to ensure that the material will be removed at any time.

9) Adjust the roll set to the correct position.When the central part of the belt conveyor runs off, the mounting holes of the roller bracket can be modified to form a long hole, with the left side of the roller group moving towards the left or the right side of the belt or the left side when the belt leans towards the right.

10) Users should choose manufacturers with good reputation and rich production experience, and be equipped with perfect technical service personnel, which can solve the use problems of users in time and implement the three guarantees of services of good products.

11) When installing the tensioning device, the center line of the belt conveyor shall be vertical to the drum shaft line of the tensioning device.The operator shall strictly follow the installation requirements and do the commissioning work.

12) The belt machine shall be repaired after a period of time, and the belt aging and deformation shall be replaced in time.

13) Correct the skew rack.The rack tilt includes the tilt of the rack centerline and the tilt of the two sides of the rack. It can only be reinstalled through the rack to ensure the leveling of the rack center line and both sides of the rack, so as to fundamentally solve the problem.

14) Find out the vibration cause and solve it in time.

15) It is best to add a pressure belt wheel at the concave section of the belt transport machine to avoid the belt bounce or wind blowing deviation. In the design stage, a concave section radius of curvature should be adopted as large as possible to avoid such situations.

During the operation of the belt conveyor, frequent attention should be paid to the deviation of the belt, correctly judge the cause of the deviation, and take appropriate exclusion measures in time to ensure the safe, efficient and stable operation of the belt conveyor.When having conditions and capabilities, the anti-bias switch can be used, or the travel switch can be designed into a safety protection alarm device to fundamentally eliminate the deviation fault of the tape, prevent the abnormal damage of the leakage of material and the equipment, and ensure the production efficiency of the equipment.

During the operation of the belt conveyor, frequent attention should be paid to the deviation of the belt, correctly judge the cause of the deviation, and take appropriate exclusion measures in time to ensure the safe, efficient and stable operation of the belt conveyor.When having conditions and capabilities, the anti-bias switch can be used, or the travel switch can be designed into a safety protection alarm device to fundamentally eliminate the deviation fault of the tape, prevent the abnormal damage of the leakage of material and the equipment, and ensure the production efficiency of the equipment.

Leave a Reply

Want to join the discussion?Feel free to contribute!