Rubber Conveyor Belt Choice Knowledge

Nylon canvas

Product features:

1. This product is made of cotton canvas (CC) or cotton cotton immersion canvas (VC) by caldering, molding, vulcanization and other processes.

2. The product is suitable for conveying non-corrosive spike-free block, granular and powder materials, such as coal, coke, sand, cement and other bulk materials (materials) or adult articles at room temperature.

3. This product meets the requirements of different use conditions, and can be made into different structures such as package edge, open edge type, middle ladder and edge ladder.

Nylon core conveyor belt

Nylon conveyor belt is made of multi-layer nylon canvas bonded together in a certain way, and the upper and lower sides are covered with strong and elastic wear-resistant rubber for conveying small and medium block, granular, powder objects, suitable for high-speed, medium and long distance impact resistance transportation.

Variety: according to the performance of the cover rubber can be divided into common use type and wear-resistant type, refractory type.

Nylon core conveyor belt has the characteristics of thin body, high strength, impact resistance, good performance, large interlayer bonding strength, excellent flexure and long service life, suitable for medium and long distance, high load and high speed conditions to transport materials.

Specification: (1) Bandwidth: 100mm-3000mm;

(2) Cloth layer: 2-8 layers;

(3) Cover rubber: working face: 1.5-8mm; non-working face: 0mm-4.5mm.

Polyfat

Polylipid conveyor belt is a multi-layer polyester (or through polyester, latitude for polyamine) canvas bonded together in a certain way, up and down the cover rubber high strength, good elastic wear rubber. For the delivery of small and medium-sized block, granular, powder and other materials. Suitable for medium and long distance, high load, high-speed conditions to transport materials.

Variety: according to the performance of the cover glue can be divided into common use of strong split type, strong wear type, general type, acid and alkali resistant type, refractory type.

Whole-core flame-retardant conveyor belt

The whole core flame retardant conveyor belt is mainly used in underground coal mine.

Features: belt body not decinating, elongation, impact resistance, tear resistance.

Flame resistance:

(1) Roller mill number: the roller surface temperature is not greater than 325℃.

(2) Spray lamp combustion: the average unflame time of the full thickness test piece is not greater than 3.0S, and the average uncover layer is not greater than 5.0S.

(3) Propane combustion: the non-destructive length is more than 250mm.

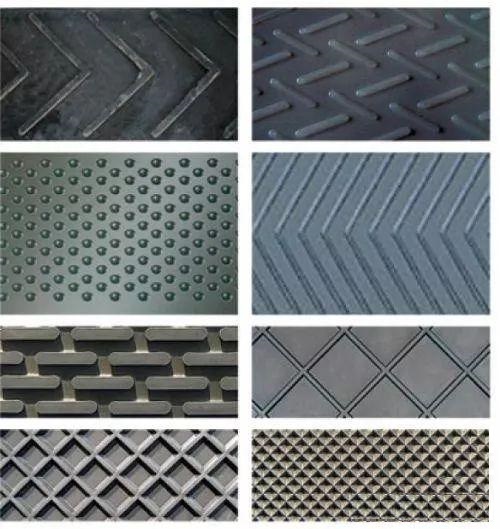

Pattern

Pattern conveyor belt is composed of belt body and pattern part. Due to the different materials transported and the inclination size of the conveyor, the shape and height of the pattern (depth) are also different.

Commonly used pattern conveyor belt varieties such as: herringbone pattern conveyor belt, eight-shaped pattern conveyor belt, fish bone pattern conveyor belt, U-shaped pattern conveyor belt, cylindrical pattern conveyor belt, hemp dot pattern conveyor belt, etc. Or designed according to the user requirements, suitable for less than 30 degrees of inclination of powder, granular, and bulk material delivery.

Scope of application and characteristics:

Widely used in port, mines, power, coal, building materials, concrete and grain and other departments to improve various materials, is a new efficient and ideal transportation equipment.

Use: Suitable for bulk material delivery below 30 degrees of inclination.

Features: to prevent the material decline, improve the transmission capacity.

The commonly used pattern conveyor belts are as follows:

★ Type V type pattern ★

Features: there is a “human” type pattern above the belt body, but the opening is also closed, each pattern can be divided into high, medium, low three kinds.

Use: suitable for 40 degrees of inclination of powder, granular, small pieces of material transport, can also transport bagged materials.

★ strip pattern ★

Features: there is the high strip pattern on the strip surface, the pattern is divided into high, middle and low three kinds, each pattern can be divided into thin and dense forms according to the arrangement spacing.

Use: Suitable for horizontal delivery of packaging at 30 degree inclination. If in the case of a slot, it can replace the human-type pattern.

★ granular pattern ★

Features: the belt surface has a granular pattern higher than the band body or concave embedded in the band body, and the pits can also be made into a square hole shape or prism and cloth pattern.

Use: The convex grain pattern is suitable for soft packaging or flexible material delivery (such as cardboard box) or no sliding delivery. Ppit-shaped granular pattern is suitable for granular delivery at 45 degree inclination.

★ fan pattern ★

Features: There is a semi-fan-shaped pattern on the belt surface. When the tape into a groove, the pattern is disturbed into a fan (or semicircular), a high pattern.

Use: Suitable for 60 degree large inclination conveying powder, particles and bulk materials.

Heat resistant conveyor belt

Heat-resistant conveyor belt is mainly used to transport high-temperature materials, such as sintered ore, hot coke, cement clinker, hot castings, etc.

According to the main performance of tropical damage resistance and loss of working ability, different heat resistance levels, use triethylene propylene or styrene butadiene rubber as the covering rubber; high strength and high permeability polyester canvas as a strong layer, and lay the heat resistant glass cloth between the covering rubber and the skeleton layer to greatly improve the heat resistance life. According to the user requirements, can be made into a endless belt.

rubber

conveyor belts

Rubber conveyor belt has the characteristics of tropical resistance, wear belt, burning belt, oil resistance belt, alkali belt, alkali belt, tropical belt, cold belt and so on. Mainly used for the mining, metallurgy, iron and steel, coal, hydropower, building materials, chemical industry, grain and other enterprises of the solid material transportation.

Fender

RUBBER CONVEYOR BELT

The common barrier rim conveyor belt is a large inclination wave-like barrier rim conveyor belt, which consists of the baseband, barrier rim and transverse partition plate. The edge plays the role of preventing material slip and falling. In order to easily bypass the drum, the gear side is designed as corrugated; the horizontal partition function is to support the material, in order to achieve large inclination transmission, using T-type TC type. The sides and transverse partition are connected to the baseband by secondary sulfation and have a high connection strength.

Large inclination

SIDEWALL CONVEYOR BELT

Fast installation speed, large transport inclination Angle, a small floor area, reduced investment in civil engineering, flexible layout, small maintenance volume, low energy consumption.

The large inclination wave retaining rim band is composed of baseband, retaining rim and horizontal partition plate. The edge plays the role of preventing material slip and falling.

In order to easily bypass the drum, the gear side is designed as corrugated; the horizontal partition function is to support the material, in order to achieve large inclination transmission, using T-type TC type. The sides and transverse partition are connected to the baseband by secondary sulfation and have a high connection strength.

Product characteristics (ordinary large inclination wave retaining edge conveyor belt):

1. Increased transmission Angle (30~90 degrees);

2. Small land area and less investment;

3. Large transportation volume and higher promotion height;

4. Smooth transition from horizontal to inclined (or vertical);

5. Suitable for conveying powder, granular, small block, paste and liquid materials;

6. Low energy consumption, simple structure, high strength of tape and long service life.

Corrugation sidewall

BELT COVNEYOR

There are skirt without partition conveyor belt and skirt with partition conveyor belt, can make all kinds of bulk materials to 0-90 degrees for any inclination Angle of continuous transportation, with large transport Angle, wide range of use, small area. No transport point, reducing civil engineering investment, low maintenance cost, large transport volume and other characteristics, to solve the ordinary conveyor belt or pattern conveyor belt can not reach the transport Angle. The wave-like retaining edge conveyor belt can be designed into a complete conveying system according to the requirements, avoiding intermittent transmission and complex conveying lifting system.

The wave-like blocking edge conveyor belt can deliver a variety of bulk materials in the horizontal, inclined, vertical and angular directions, from coal, ore, sand to fertilizer and grain. The particle size of the material is not limited, from a very small particle size to 400mm, and the delivery volume can be from 1 cubic meter / hour to 6,000 cubic meters / hour.

Acid and alkali resistant conveyor belt

CONVEYOR BELTING

Choose cotton canvas, nylon canvas or polyester canvas for the core, with good body elasticity, good groove performance, the use of small elongation. The acid and alkali resistant materials has good chemical corrosion resistance and good physical properties.

Use: Suitable for chemical plants, chemical fertilizer plants, paper mills and other factories and mining enterprises to transport acid and other corrosive materials. It can also be used for seawater and salt drying.

(1) Core materials: NN100, NN150, NN200, NN250, NN300, NN350, NN400, NN450, NN500EP100, EP150, EP200, EP250, EP300, EP350, EP400, EP450, EP500;

(2) Bandwidth: 100mm-3000mm;

(3) Cloth layer: 1-10 layers;

(4) Cover glue: working face: 1.5-8.0mm; non-working face: 1.5-4.5mm.

Acid and alkali resistant conveyor belt is divided into many specifications and models according to the use environment and requirements: according to the size of the transportation volume, such as: B500, B600, B650, B800, B1000, B1200, B1400, B 1400, B1600, B1800, B2000 and other common model by width (B represents the width, in mm).

Resistant burning

CONVEYOR BELTS

It is composed of high temperature resistant burning layer, transition layer, organic heat insulation layer, strong layer and heat resistance layer.

Characteristics: The covering glue produces the microporous carbonization layer at high temperature, which can resist burning and prevent the further transmission of heat to the belt body, and reduce the internal strength of the tape. The carbonization layer in the belt body operation process, the formation of irregular small cracks, using the belt body cooling.

The inorganic material with diameter structure is used as the skeleton material of burning resistant conveyor belt. The use of this skeleton material solves the difficulty of high temperature carbonization, nylon and polyester canvas of cotton canvas used in the past, and has the characteristics of small strength loss and no shrinkage deformation at high temperature.

The unique adhesive formula design ensures that the bonding strength between the adhesive material and the skeleton material is much higher than that of the ordinary tropical resistance, and the bonding strength between the layers in the high temperature state is 3N and mm. Bearing material temperature of 200- -600℃, instantaneous 800℃.

Cold-resistant

RUBBER CONVEYOR BELTSCharacteristics: choose cotton canvas, nylon canvas or polyester canvas as the core, covering rubber using natural rubber and butding rubber, with high elasticity, impact resistance, cold resistance and other characteristics, can be used normally in the environment of minus 40℃.

qualification:

1. According to the performance of the cover rubber, the cold-resistant conveyor belt is divided into three types: crack resistance (H), wear resistance (D) and general type (L).

2. According to cold tolerance, C1 and C2. Operating ambient temperature is-45- -50℃; operating ambient temperature is-60- -50℃.

specifications:

(1) Belt core material: NN100, NN150, NN200, NN250, NN300, NN350, NN400, NN450, NN500;

(2) Bandwidth: 100mm-3000mm;

(3) Cloth layer: 1-10 layers;

(4) Cover glue: working face: 1.5-8.0mm; non-working face: 1.5-4.5mm.

How to choose the wear-resistant conveyor belt

How to choose the wear-resistant conveyor belt? We basically choose the conveyor belt, and we have to compare not only the price, but also the quality of the wear-resistant conveyor belt. If you choose bad conveyor belts, you can’t see the surface. We have a lot of trouble when we use it. We will save more time and energy when using conveyor belts. Although wear-resistant conveyor is common, it plays a vital role in the normal operation of the entire production system. In many cases, the failure may occur during the use process, and the failure of the wear-resistant conveyor belt usually appears as the failure of the conveyor chain, which is the main component, and is an important traction device. Therefore, we can also see the transmission chain corresponding to each other. The advantages of component selection play a key role in the normal and stable operation of the wear-resistant conveyor belt.

The use of wear-resistant conveyor belts in every plant is very common because many industrial production may require the use of wear-resistant conveyor belts to achieve faster and more efficient work. However, it also has some impact on the work when we use this type of conveyor belt. When we use it, we do not take the lubrication work seriously. The impact is also great. Mechanically, this is very important because the transport chain is not completely lubricated if the lubricant is not used for a long time. If used for too long, there will be a certain degree of wear and corrosion, resulting in the chain loose or kink.

In fact, our life requires us to constantly observe and improve, including our mechanical equipment, understand some of the failure and even other problems. We need to explore and solve, to reduce the failure rate and maintenance cost of the wear-resistant conveyor belt as much as possible, and can replace the transformation with the telescopic conveyor belt and the wear-resistant conveyor belt technology. It eliminates many hidden dangers, meets production needs, and reduces production costs. This gradual improvement will make everyone prefer a wear-resistant conveyor belt.

Leave a Reply

Want to join the discussion?Feel free to contribute!