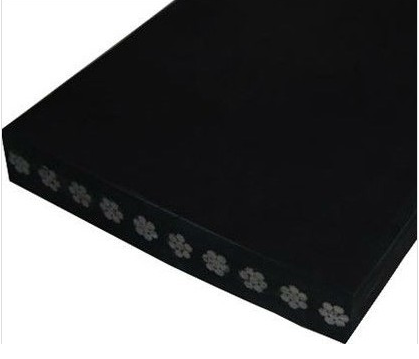

Steel Wire cord conveyor belts

Steel cord wire rope conveyor belt is a rubber conveyor belt based on steel wire.It has the advantages of large tensile strength, good impact resistance, long life, small elongation, good groove formation and good flexibility resistance, It is suitable for long distance, large range and high speed conveying materials.The product is made up of core glue, wire rope, cover rubber and edge rubber

Usage

Steel wire rope conveyor belt is suitable for the delivery of materials under the tear prevention conditions required in coal mines, mines, ports, electric power, metallurgy, building materials and other industries, and can be used for the delivery of long distance, large span, large volume and high speed materials.

Characteristic

The wire rope conveyor belt is composed of core glue, wire rope, cage cover layer and edge glue, which has advantages such as mildew prevention, moth decay prevention, aging prevention, good heat resistance, high tear resistance strength and can be renovated after bad use.Features a large tensile strength.Good impact resistance, long life, small elongation, good groove formation, flexible resistance is good for long interval, large transport range, high speed delivery of materials.

Feature

- High allowable use intensity and high safety factor;

- Very small elongation and short tension travel distance;

- Strong combination of steel wire rope and rubber, and excellent dynamic performance;

- Soft band body, good groove formation, and good straight line operation;

- Excellent impact resistance performance;

- Reliable joints and long service life.

Technical function

(1) All performance in accordance with GB9770;

(2) Performance users of covering rubber, please contact us if we have special requirements;

(3) Impact resistance and tear resistance can improve impact resistance by 1~2 times, and tear resistance by 0.5~1 times;

(4) Minimum working temperature of cold resistance type is-60℃.

Classify

- According to structure: ordinary type and impact resistance and tear resistance type.

- According to the use: in addition to ordinary types, there are wear resistance, heat resistance, cold resistance, acid and alkali resistance, flame resistance, tear resistance, refractory, ozone resistance and other types.

3, Variety: according to the cover rubber performance can be divided into: ordinary wire core conveyor, flame retardant wire core conveyor, cold resistant wire core conveyor, oil resistant wire core conveyor, flame retardant wire core conveyor, etc.The intensity is higher than ordinary transport belt and length, which can reduce the conversion station, save power and treatment consumption.

Damage form

Damage of wire rope conveyor belt has various forms, mainly: serious wear on upper adhesive surface; pull edge; tear.Among them, the conveyor belt tear is one of the most harmful forms of damage, it mainly refers to the sharp impurities in the conveyor material inserted into the conveyor belt or the steel wire extraction in the conveyor belt caused by the longitudinal tear.Although the conveyor belt tear is an accidental damage, it is very destructive. Without timely control, the whole conveyor belt will tear (accidents that tear kilometers of conveyor belt occur in the port), which will stop production and bring huge direct and indirect economic losses to the port.Therefore, the protection and testing of the conveyor belt tear has been paid attention to by the conveyor belt manufacturers and users.Meanwhile, the relevant national standards also require that conveyor belts should be installed to prevent longitudinal tear and tear testing devices.

Implement the standards and the main indicators

GB / T9770-2001, Q / FXS05-2002, ozone-resistant Q / FXS06-2002, flame-refractory G2539-93, acid-resistant Q / FXS02-2002, heat-resistant Q / FXS08-2001, tear-resistant HG / T3646-1999, flame-resistant MT668-1997.

| Products, species | Standards and main indicators |

| General type steel wire rope core conveyor belt | GB/T9770-2001 |

| Flame-retardant steel wire rope core conveyor belt | MT668-1997 |

| General flame retardant steel wire rope core conveyor belt | MT668-1997 |

| Heat-resistant steel wire rope core conveyor belt | HG2297-92 |

| Wear-resistant steel wire rope core conveyor belt | Shaber mill consumed 90mm 3 |

| Acid-resistant, alkali, oil-type wire rope core conveyor belt | HG4-846 |

| Cold-resistant steel wire rope core conveyor belt | Crisagile temperature-40℃ |

| Item, eye | St

630 |

St

800 |

St

1000 |

St

1250 |

St

1600 |

St

2000 |

St

2500 |

St

3150 |

St

3500 |

St

4000 |

St

4500 |

St

5000 |

St

5400 |

| Longitudinal tensile strength is N/mm | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 |

| Maximum nominal diameter mm | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 6.0 | 7.2 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 | 11.3 |

| Wire rope spacing is mm | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Upper overlay thickness is mm | 5 | 5 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8.5 | 9 |

| The lower overlay layer thickness is mm | 5 | 5 | 6 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8.5 | 9 |

| Width specification is mm | Steel, silk, rope, root, count | |||||||||||||||||

| St

630 |

St

800 |

St

1000 |

St

1250 |

St

1600 |

St

2000 |

St

2500 |

St

3150 |

St

3500 |

St

4000 |

St

4500 |

St

5000 |

St

5400 |

||||||

| 800 | 75 | 75 | 63 | 63 | 63 | 63 | 50 | 50 | 50 | |||||||||

| 1000 | 95 | 95 | 79 | 79 | 79 | 79 | 64 | 64 | 64 | 64 | 59 | 55 | 55 | |||||

| 1200 | 113 | 113 | 94 | 94 | 94 | 94 | 76 | 76 | 77 | 77 | 71 | 66 | 66 | |||||

| 1400 | 133 | 133 | 111 | 111 | 111 | 111 | 89 | 89 | 90 | 90 | 84 | 78 | 78 | |||||

| 1600 | 151 | 151 | 126 | 126 | 126 | 126 | 101 | 101 | 104 | 104 | 96 | 90 | 90 | |||||

| 1800 | 171 | 143 | 143 | 143 | 143 | 114 | 114 | 117 | 117 | 109 | 102 | 102 | ||||||

| 2000 | 159 | 159 | 159 | 159 | 128 | 128 | 130 | 130 | 121 | 113 | 113 | |||||||

| 2200 | 176 | 141 | 141 | 144 | 144 | 134 | 125 | 125 | ||||||||||

| 2400 | 193 | 155 | 155 | 157 | 157 | 146 | 137 | 137 | ||||||||||

| 2600 | 209 | 168 | 168 | 170 | 170 | 159 | 149 | 149 | ||||||||||

| 2800 | 194 | 194 | 171 | 161 | 161 | |||||||||||||

| Level code | Tensile strength, MPa | Pull-off elongation rate,% ≥ | Minding consumption, mm 3 | |||||||||||||||

| D | 18 | 400 | 90 | |||||||||||||||

| H | 25 | 450 | 120 | |||||||||||||||

| L | 20 | 400 | 150 | |||||||||||||||

| P | 14 | 350 | 200 | |||||||||||||||

Leave a Reply

Want to join the discussion?Feel free to contribute!