What is rubber conveyor belt

Rubber conveyor belt has many type such as heating resistant belt, abrasion-proof rubber conveyor belt, fire resistant rubber conveyor belt, oil resistant rubber conveyor belt, alkali resistant rubber conveyor belt, alkali resistant rubber conveyor belt, cold resistant rubber conveyor belt and other characteristics. Mainly used in mining, metallurgy, iron and steel, coal, hydropower, building materials, chemical, food and other enterprises of solid material transportation.

The rubber conveyor belt usage

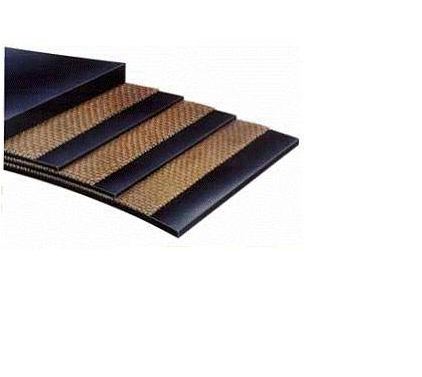

The rubber conveyor belt is the main part of the belt conveyor, which is mainly used for the large-scale continuous transportation of coal, mining, metallurgy, chemical industry, construction and transportation departments. The materials transported are divided into block, powder, paste and adult items, etc. From the perspective of micro-composition, the conveyor belt is mainly composed of three parts: skeleton material, covering layer and base material, among which the overlay layer is the key part of determining its performance and use.

According to the raw materials used in the over layer, the conveyor belt industry can be divided into two categories: heavy conveyor belt and light conveyor belt. The former takes rubber (including natural glue and synthetic glue) as the main raw material, so also known as rubber conveyor belt, and its use scope is concentrated in heavy industry and infrastructure construction; the latter mainly uses polymer materials, mainly used in light industry such as food and electronics.

Rubber conveyor belt Joint method

All the conveyor belts must be annular for use, so the quality of the conveyor belt joint directly affects the service life of the conveyor belt and the smooth operation of the conveyor line.The common methods of general conveyor belt joints are mechanical joints, cold bonding joints, hot sulfur joints, etc.

Mechanical splice

Generally refers to the use of belt buckle joint, this joint method is convenient and convenient, but also more economical, but the efficiency of the joint is low, easy to damage, which has a certain impact on the service life of the conveyor belt products.In the PVC and PVG, products below grade 8.Connecting with a buckle corresponds to 28% -45% of the conveyor belt’s own strength.

Cold adhesive head

That is, the cold adhesive adhesive is used to make the joint.This joint method is higher than the mechanical joint, more economical, should be able to have a better joint effect, but from practice, because the process conditions are more difficult to master, in addition, the quality of the adhesive has a great impact on the joint is very large, so it is not very stable.A cold adhesive bond is equivalent to 40% -55% of the strength of the conveyor belt itself.

Heat-sulfur joints

Practice has proved to be the most ideal joint method, can ensure high joint efficiency, but also very stable, the joint life is also very long, easy to master.However, there are the disadvantages of process trouble, high cost, long joint time and so on.Binding with mechanical thermal sulfide is equivalent to 60% -80% of the strength of the conveyor belt itself.

classify

Wire rope core conveyor belt

conveyor belt made of rubber with steel core liner as traction and carrier member of belt conveyor.

Characteristics of steel rope core conveyor belt: large tensile strength, good impact resistance, long life, small use elongation, good groove formation, good flexure resistance, suitable for long distance, large transportation range, high speed conveying materials. The product is made up of core glue, wire rope, coverslips and edge glue.

Steel rope core conveyor belt varieties, can be made into a pipe type according to the customer demand.

According to the cover rubber performance can be divided into: ordinary, flame retardant, energy saving, heat resistant, wear resistant, cold resistant, acid and base resistant, oil resistant and other varieties.

Use of steel rope core conveyor belt: widely used in coal, mine, port, metallurgy, electric power, chemical and other fields.

Fabric core conveyor belt

Fabric core conveyor belt is set for the purpose of conveying various special performance items under different regions and environmental conditions, conveyor belt core skeleton structure, mainly for cold resistance, oil resistance, heat resistance, high temperature resistance, chemical corrosion resistance conveyor belt supporting belt core.

It can be applicable to different regions, different hot and cold conditions, as well as various food, chemical products and other bulk materials under different conditions.Ordinary conveyor belt is widely used in building materials, chemical, coal, power, metallurgy and other departments, suitable for conveying non-corrosive block, grain, powder, such as coal, coke, sand, cement and other bulk (materials) or adult goods, conveying various bulk, grain, powder and other loose materials with accumulation density of 6.5t~2.5t/m, can also be used for the delivery of adult goods.

Matters need attention

Avoid the roller is covered by the material, resulting in poor rotation, prevent the leakage from being stuck between the drum and the tape, pay attention to the lubrication of the active part of the conveyor belt, but not oil conveyor belt;

Prevent the conveyor belt load to start;

If the conveyor belt deviation, timely measures shall be taken to correct it;

When the conveyor belt is partially damaged, apply Kate 90T high curing rubber repair cream or Forthorn rubber repair materials to repair in time to avoid expansion;

Avoid the conveyor belt from rack, pillar or block block to prevent cracking.

Characteristics of the conveyor belt industry

With the popularity of conveyor belt in industrial production, multi-variety, high performance, lightweight, multi-functional, long life are several aspects of producers.In industrial production, the correct use of conveyor belt is particularly important, in the use of conveyor belt should be paid attention to the following matters:

- Avoid the roller being covered by the material, causing poor rotation, prevent the leakage from being stuck between the roller and the tape, pay attention to the lubrication of the active part of the conveyor belt, but not the oil conveyor belt;

- Prevent the conveyor belt load to start;

- If the conveyor belt deviation, timely measures should be taken to correct;

- When the conveyor belt is partially damaged, artificial cotton should be used to repair it in time, so as to avoid expansion;

- Avoid the conveyor belt from rack, pillar or block block to prevent breaking and cracking

Debug method

The conveyor belt is the key equipment of the conveying system, and its safety and stable operation directly affects the production operation.The deviation of conveyor belt is the most common fault of belt conveyor, and its timely and accurate treatment is the guarantee of its safe and stable operation.There are many phenomena and reasons for deviation. We need to take different adjustment methods according to different deviation phenomena and reasons, so as to effectively solve the problem.This paper is based on the years of field practice and from the mechanical principle to analyze and explain the causes of such faults.

The axis of the head drive roller or the rear change to the roller is not perpendicular to the center line of the conveyor, causing the conveyor belt to deviate from the head roller or the rear change to the roller.When the roller is disinclined, the tightness of the conveyor belt on both sides of the roller is inconsistent, and the traction force Fq along the width direction is inconsistent, into an increasing or decreasing trend, which will make the conveyor belt add a decreasing moving force Fy, resulting in the conveyor belt running deviation to the loose side, the so-called “loose and not tight”.The adjustment method is as follows: for the head roller such as the conveyor belt deviation to the right side of the roller, the bearing seat on the right side shall move forward, and the conveyor belt deviation to the left side of the roller is repeatedly adjusted until the conveyor belt is adjusted to the ideal position.It is best to install the position accurately before adjusting the drive or reversing the roller.

The machining error of the roller, uneven diameter size, and the conveyor belt will deviate to the side with a larger diameter.That is, the so-called “run big do not run small”.The traction force Fq of the conveyor belt produces a moving dividing force Fy towards the large diameter side, and the conveyor belt produces shifts under the dividing force Fy.For this case, the solution is to clean up the surface of the roller adhesive, processing error and uneven wear will be replaced down and reprocess the glue treatment.

The improper location of the reprint point causes the deviation of the conveyor belt. The drop position of the material at the reprint point has a great impact on the deviation of the conveyor belt, especially when the projection of the upper conveyor and this conveyor in the horizontal plane is more vertical.The relative height of the two belts at the reprint point should usually be considered.The lower the relative height, the greater the horizontal velocity component of the material, the greater the lateral impact force Fc on the lower belt, and the material is also difficult to medium.Deflection the material on the cross section of the conveyor belt and the horizontal force Fy of impact force Fc eventually bias the belt.If the material goes to the right, the belt runs to the left and vice versa.For the deviation in this case, the relative height of the two conveyors should be increased as much as possible during the design process.The form and size of the upper and lower funnel and guide tank of the belt conveyor should be considered more seriously in the space limitation.The width of the general guide groove should be about three-fifths of the width of the belt.To reduce or avoid belt deviation, increase the baffle to block the material and change the falling direction and position of the material.

The perpendicular error of the installation position of the bearing roller group and the center line of the conveyor is large, resulting in the deviation of the conveyor belt to one piece in the bearing section.The conveyor belt runs forward and gives the roller a forward traction force Fq, which decomposes into the dividing force Fz that turns the roller and a lateral dividing force Fc, which makes the roller move axially. Since the fixed roller of the roller bracket cannot move axially, it will inevitably produce a reaction force Fy on the conveyor belt, which moves the conveyor belt to the other side, resulting in running deviation.Knowing the force situation of the load roller group installation deflection, it is not difficult to understand the deviation of the conveyor belt, and the adjustment method is clear.

The first method is to process the growth holes on both sides of the roller set for adjustment.

The second method is to install the center roll set, there are a variety of types such as intermediate shaft, four link, vertical roller, etc. The principle is to use the block or roll in the horizontal direction rotation block or produce horizontal thrust to make the belt automatically centered to adjust the belt running deviation, the same force situation and carrying the roll set bias force situation.Generally, it is more reasonable to use this method when the total length of the belt conveyor is short or when the belt conveyor is running two-way, because the shorter belt conveyor is easier to deviate and not easy to adjust.This method is best not used for the long belt conveyor, because the use of the centering roller set will have a certain impact on the service life of the conveyor belt.

Running deviation problem

There are many reasons for the deviation, which need to be handled differently according to different reasons.

1.Adjust the bearing roller set

The belt of the belt machine can adjust the position of the roller set during the central deviation of the whole belt conveyor; and the mounting holes on both sides of the roller set are processed with growth holes for adjustment.The specific method is which side of the belt bias, which side of the roll group moves forward towards the forward direction of the belt, or the other side moves back.If the belt runs upward, the lower position of the roller group shall move to the left and the upper position of the roller group to the right.

2.Install the dial support roller set

There are many types of centering roll group, such as intermediate rotation shaft, four link, vertical roller, etc. The principle is to use the block or roll in the horizontal direction to block or produce horizontal thrust so the belt automatically centered to achieve the purpose of adjusting the belt deviation.Generally, this method is reasonable to use the total length of the belt transport machine is short or when the belt transport machine runs two-way, because the shorter belt conveyor is easier to deviate and not easy to adjust.This method is best not to use in the long belt conveyor, because the use of the centering roller set will have a certain impact on the service life of the belt.

- Adjust the position of the drive roller and the redirection roller

The adjustment of drive roller and redirection roller is an important link of belt running deviation adjustment.Because one belt conveyor has at least two to 5 rollers, the installation position of all rollers must be perpendicular to the center line of the length of the belt conveyor, and the deviation is too large.The adjustment method is similar to that of the adjustment roll set.For the head roller, if the belt runs to the right side of the roller, the right bearing seat should move forward, the belt runs to the left side of the roller, then the left bearing seat should move forward, corresponding to the left bearing seat or the right bearing seat back.The tail roller is adjusted exactly the opposite way of the head roller.Repeated adjustment until the belt is adjusted to the more ideal position.It is best to install the position accurately before adjusting the drive or reversing the roller.

4.Adjustment of the tension position

The adjustment of belt tension is a very important part of the adjustment of belt conveyor running deviation.The two turning rollers at the upper part of the heavy hammer tension shall be perpendicular to the belt length of the gravity vertical, that is, to ensure the level of the shaft centerline.When using screw tension or hydraulic cylinder tension, the two bearings of the tension roller shall be shifted simultaneously, to ensure that the roller shaft is perpendicular to the longitudinal direction of the belt.The specific belt deviation is similar to the adjustment at the roller.

- The impact of the material drop position at the reprint point on the belt deviation

The drop position of the material at the reprint point has a great impact on the deviation of the belt, especially when the two belt machines in the horizontal plane is vertical.The greater the lateral impact on the lower belt, and the material is also difficult to medium.Skew the material across the belt section and eventually bias the belt.If the material goes to the right, the belt runs to the left and vice versa.The relative height of the two belts should be increased as much as possible during the design process.The form and size of the upper and lower funnel and guide tank of the mobile bulk transport machinery should be more seriously considered.The width of the general guide groove should be about two-thirds of the width of the belt.

Maintenance for rubber conveyor belt

The conveyor belt shall be kept clean to avoid direct sunlight, rain and snow immersion, to prevent contact with acid, alkali, oil, organic solvents and other substances that affect the quality of rubber, and 1 meter away from the heating device.

During storage, the warehouse temperature should be kept between-15℃ – – + 40℃, and the relative humidity should be maintained between 50-80%.

Storage conveyor shall be placed in volume and shall not be folded and flipped quarterly during placement.

The operation speed of the conveyor belt shall not be greater than 5.0 m / second, large transportation mass and materials with large wear and tear shall be used at low speed when using the fixed plough unloading device.Beyond the specified speed, the tape service life will be affected.

The relationship between the diameter of the conveyor transmission roller and the conveyor belt cloth layer, the matching of the transmission roller and the requirements of the roller groove corner shall be reasonably selected according to the design provisions of the conveyor.

To reduce the impact and wear of the tape, the feed direction shall follow the operating direction; the material drop to the tape shall be minimized; the feed port shall avoid directly above the roller or roller; the tape receiving section shall shorten the roller spacing and take buffer measures.In order to prevent scraping tape, the rubber plate of the scraper cleaning device and unloading device shall be in contact with the tape, and no tape head with cloth layer shall be used.

The following matters should be paid to the conveyor belt during use:

- Avoid the roller being covered by the material, resulting in poor rotation, prevent the leakage material from being stuck between the roller and the tape, pay attention to the lubrication of the active part, but not the oil conveyor belt.

- Strive to avoid the start with load.

- If the tape deviates, measures shall be taken to correct it in time.

- Local damage to the adhesive tape should be repaired in time to avoid expansion.

- Avoid tape block from rack, pillar or block material to prevent breaking and cracking.

Injury prevention

Damage and cause

- Local wear (epidermal damage)

Fabric core conveyor belt, steel wire core conveyor belt are very prone to such damage.The main reason is that the reprint place, guide tank, invalid roll and other parts are easy to jam the large material blocks. Once the conveyor belt runs up, it must cause the local excessive wear of the conveyor belt.In the coal loading and unloading system of Rizhao Port, the cantilever belt such as reactor and feeder had been locally ground to 5 layers of canvas in the conveyor belt and other parts were better covered. In the loading system, a belt was directly stuck to the belt due to the low guide tank skirt plate, resulting in the steel wire grinding out at all the skirts on both sides of the belt.

- Local crushing (through-through injury)

Fabric core conveyor belt and wire core conveyor belts have such damage.When the conveyor belt delivers materials, there are often large stones and more sharp materials blocks, and these materials blocks are in the transfer junction because there is not enough buffer, breaking the conveyor belt with a large impact force, forming a hole.If the material is mixed with sharp objects, such as an iron crowbar, it is easy to break the conveyor belt, resulting in a large tear of the conveyor belt.

- Injury to the adhesive site

The conveyor tape adhesive site is rebonded when the tape is installed.If the joint part is not handled well, it is easy to cause premature wear of the joint part, opening glue peeling and other phenomena.If it is not handled in time, the joint site damage deterioration speed is fast, easy to occur broken belt accident.

- Vertical crack of steel wire core conveyor belt

Some steel wire core conveyor belt often appear longitudinal penetrating scratches, up to dozens of meters or even hundreds of meters long, such damage is generally known as longitudinal crack.Most of the reasons for the weapon stuck in some places, such as the scraper cleaner, the operator did not clean up in time, after the belt operation caused a long distance of the conveyor belt scratch and tear.[2]

Damage repair

During the use of conveyor belt, there are many forms of damage, such as edge lamination, ulceration, defect and cracking, long distance longitudinal tear, deep scratches, holes, large wear, covering rubber drum or peeling, joint internal defects, etc.Among them, the longitudinal tear is the most urgent, the edge damage is the most common, the joint internal defects are difficult to avoid, and the service life after repair is the most concerned.

There are three main repair methods commonly used for the conveyor belt

Thermal repair method: usually use special repair device, sulfide machine and suitable thermal sulfide material of the conveyor belt to carry the same strength of “no trace” repair of the conveyor belt.This repair can make the conveyor belt completely eliminate the damage and restore its original state.Suitable for the more important, long distance, high speed operation, large volume transport system.Of course, dedicated equipment and professionals are required for completing such maintenance.It is the most reliable and ideal method of conveyor belt maintenance.

Cold repair method: usually use special cold adhesive and special tools to repair the damaged parts of the conveyor belt to achieve the purpose of continuous operation.Clearly, this filling repair is expedient.Therefore, its main purpose is: to timely cold repair in the conveyor belt damage, to prevent the damage site of the conveyor belt, so as to effectively protect the core of the conveyor belt from damage, so as to wait and obtain the time and opportunities needed for repair.

Mechanical repair methods: usually use clips, nails, connecting plates, and screws or metal soft wires and special appliances made of metal materials to fix or connect the damaged parts of the conveyor belt to achieve the purpose of maintaining the operation.Even in many times today, and on many occasions, this seemingly simple, rough, and even ugly treatment can achieve emergency functions and get twice the result with half the effort.

To sum up, the most ideal and perfect repair of the conveyor belt must be strictly in strict accordance with the principle of “equal strength, the same life”, that is, thermal repair technology and technology can be realized.And the application of other repair technology, its real purpose is to obtain the appropriate repair time and opportunities.Therefore, cold repair and mechanical repair must not be regarded as the final treatment of conveyor belt damage.Only the picture is convenient, simple, the pursuit of low cost, short time, the result is most likely to be endless consequences.We hope that every conveyor belt system management and maintenance staff, must clearly understand and thoroughly understand the basic concept of conveyor belt repair, and successfully and successfully complete the bonding and maintenance work of the conveyor belt.

Leave a Reply

Want to join the discussion?Feel free to contribute!